loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Design for GRP Sectional Panel Water Storage Tank Solutions

Understanding GRP Sectional Panel Tanks A Comprehensive Overview

Glass-Fused-to-Steel (GRP) sectional panel tanks have emerged as a reliable and efficient solution for water storage in various applications, ranging from residential, commercial, to industrial uses. Their unique design, durability, and versatility make them an excellent choice for a wide array of environments. This article aims to explore the characteristics, benefits, applications, and installation processes associated with GRP sectional panel tanks.

What are GRP Sectional Panel Tanks?

GRP sectional panel tanks are modular water storage systems made from Glass-Reinforced Plastic (GRP). These tanks consist of individual panels that can be assembled on-site to form a water storage unit of varying sizes and capacities. The panels are manufactured using high-quality materials, which provide excellent resistance to corrosion, ensuring the longevity of the tank even in harsh environmental conditions.

Key Characteristics

1. Modular Design The sections can be customized to create tanks of different shapes and sizes, allowing for flexibility in installation and use. This modularity is particularly advantageous for sites with space constraints.

2. Corrosion Resistance GRP is inherently resistant to corrosion, which makes these tanks ideal for long-term water storage. They do not rust or degrade under exposure to moisture, making them suitable for both potable water and wastewater applications.

3. Lightweight Compared to traditional steel or concrete tanks, GRP tanks are significantly lighter. This characteristic simplifies transportation and makes installation easier and more cost-effective.

4. Low Maintenance GRP sectional tanks require minimal maintenance, primarily due to their durability and corrosion resistance. Regular inspections and cleaning are usually sufficient to keep them in good working order.

5. Thermal Insulation These tanks offer good thermal insulation properties, helping to maintain the temperature of the water stored within, which is particularly important for applications requiring certain temperature ranges.

Benefits of GRP Sectional Panel Tanks

1. Cost-Effectiveness While the initial investment may be higher compared to some alternatives, the longevity and low maintenance costs of GRP tanks result in significant savings in the long run.

2. Environmentally Friendly GRP materials are often produced with sustainability in mind, and the reduction in the need for frequent replacements due to their durability contributes to lower environmental impact.

3. Easy Installation The modular sections can be assembled quickly and easily on-site, reducing labor costs and timeframes for installation. This makes GRP tanks a convenient option for urgent projects or remote locations.

4. Highly Customizable Tanks can be tailored to specific user needs, including size, shape, and additional features such as insulation, ventilation, and access points.

grp sectional panel tank

Applications of GRP Sectional Panel Tanks

The versatility of GRP sectional panel tanks lends them well to a wide range of applications, including

- Drinking Water Storage With appropriate lining and treatment, these tanks can safely store potable water, meeting specific health and safety standards required for drinking water facilities.

- Fire Protection Systems GRP tanks can serve as reservoirs for firefighting needs, supplying water to sprinkler systems and fire hose connections in residential and commercial buildings.

- Agricultural Uses Many farms utilize GRP tanks for the storage of irrigation water, ensuring a steady supply during dry spells

.- Industrial Applications Industries often require large volumes of water for processes, cooling, and various operations. GRP sectional tanks can easily meet these demands while being resilient against chemically aggressive environments.

Installation Process

The installation of GRP sectional panel tanks involves several steps

1. Site Preparation Ensure the ground is level and adequately prepared to support the tank’s weight.

2. Panel Assembly Begin assembling the panels according to the predetermined design. This typically requires bolts and seals to ensure they fit together securely.

3. Installation of Accessories Add any necessary fittings, such as inlets, outlets, and overflow systems.

4. Final Inspections Conduct thorough inspections to ensure integrity and check for leaks.

5. Water Filling and Testing Once the installation is complete, fill the tank with water and perform tests for quality and stability before full operation.

Conclusion

GRP sectional panel tanks stand out as a modern solution for water storage needs, combining durability, flexibility, and efficiency. Their modular nature and cost-effectiveness make them suitable for diverse applications across various sectors. As the world continues to prioritize sustainable and reliable water management solutions, GRP sectional panel tanks will increasingly play a vital role in meeting both current and future water storage demands. Understanding these tanks and their applications is essential for anyone involved in water management or infrastructure planning.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

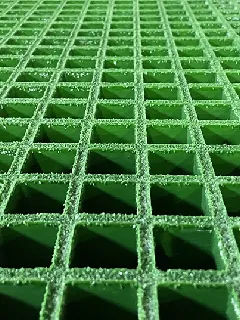

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025