loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

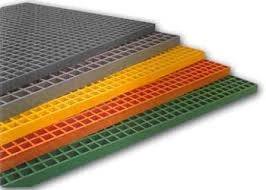

grp mesh grating

Understanding GRP Mesh Grating An Overview

GRP mesh grating, or Glass Reinforced Plastic mesh grating, is an innovative material that has become increasingly popular in various industries due to its unique properties and advantages. Composed of a matrix of fiberglass and resin, GRP mesh grating offers a lightweight, strong, and corrosion-resistant option compared to traditional materials such as steel or aluminum. This article will explore the advantages, applications, and installation considerations of GRP mesh grating.

Understanding GRP Mesh Grating An Overview

In addition to its strength and lightness, GRP mesh grating is also highly resistant to corrosion. Unlike metal grates, which can be prone to rust and deterioration when exposed to moisture or harsh chemicals, GRP mesh remains unaffected in corrosive environments. This makes it an ideal choice for applications in industries such as wastewater treatment, chemical processing, and marine environments, where traditional materials may fail.

grp mesh grating

Another noteworthy advantage of GRP mesh grating is its non-slip surface. It is designed to provide excellent traction, reducing the risk of slips and falls in environments that may be wet or hazardous. This feature is particularly important in industrial settings, where safety is paramount. Furthermore, GRP grating is available in various surface textures, allowing for customized solutions that meet specific safety standards.

The versatility of GRP mesh grating extends to its aesthetic appeal as well. Available in multiple colors and finishes, it can fit seamlessly into different design schemes, making it suitable for both functional and decorative applications. Whether used in flooring, walkways, or platforms, GRP mesh grating can enhance the visual appeal while providing practical solutions for load support and safety.

When considering the installation of GRP mesh grating, it is essential to account for specific factors. The grating is available in various sizes and configurations, allowing for customization depending on the application requirements. Proper support and anchoring are crucial during installation to ensure durability and effectiveness. Additionally, while GRP mesh grating is resistant to many environmental factors, it is advisable to periodically inspect and maintain the grating to prolong its lifespan, especially in demanding environments.

In conclusion, GRP mesh grating stands out as a superior alternative to traditional materials in various applications. Its lightweight nature, exceptional strength, corrosion resistance, non-slip surfaces, and aesthetic flexibility make it a practical and efficient choice for industries ranging from construction to marine applications. As the demand for innovative and durable building materials continues to grow, GRP mesh grating is poised to play an increasingly important role in modern construction and infrastructure projects. By understanding its key features and considering proper installation methods, businesses and builders can harness the full potential of GRP mesh grating for their projects, ensuring safety, performance, and longevity.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025