loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Grating Solutions for Enhanced Optical Performance in Advanced Applications

Understanding GRP Grating Systems Applications and Benefits

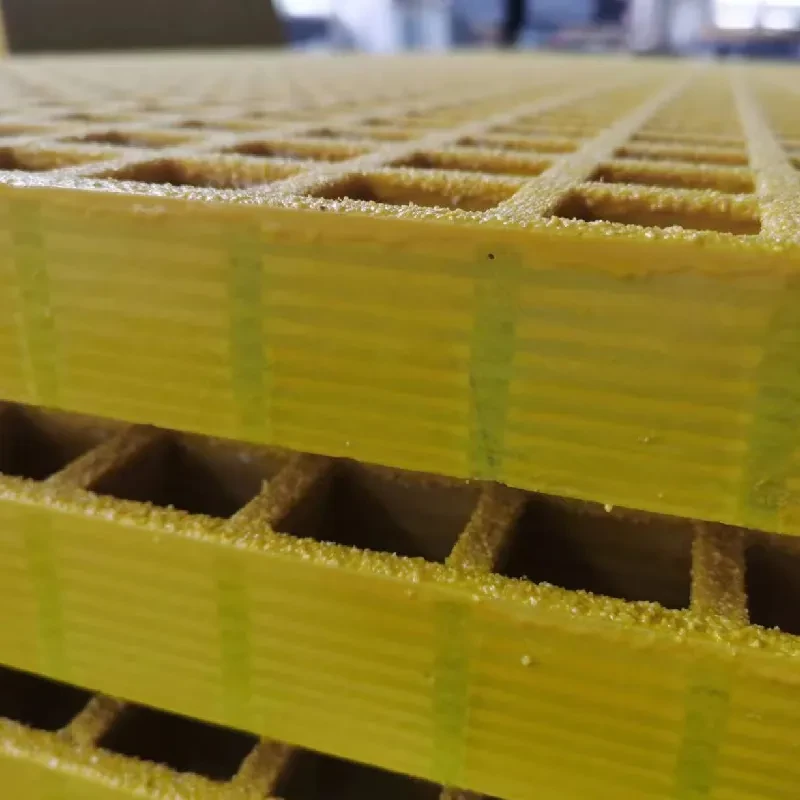

Glass Reinforced Plastic (GRP) grating systems have emerged as a popular choice in various industrial applications due to their unique properties and advantages. These systems are fabricated from a composite material, primarily composed of fiberglass reinforced with a thermosetting resin, which creates a lightweight yet strong material. In this article, we will explore the features, applications, and benefits of GRP grating systems.

Key Features of GRP Grating Systems

1. Corrosion Resistance One of the most significant advantages of GRP gratings is their resistance to corrosion. Unlike traditional materials such as steel, GRP does not rust or corrode when exposed to harsh chemicals or weather conditions. This property makes GRP grating systems ideal for use in environments that require a durable and long-lasting solution, such as chemical plants, wastewater treatment facilities, and coastal areas.

2. Lightweight Design GRP grating systems are remarkably lightweight compared to steel or aluminum alternatives. This lightweight nature not only makes them easier to handle and install, but it also reduces the load on supporting structures. As a result, project costs can be minimized, and installation times are often reduced.

3. High Load Capacity Despite their lightweight composition, GRP grating systems can support significant loads thanks to their engineered design. They are available in various thicknesses and configurations, allowing them to meet the specific load-bearing requirements of different applications.

4. Fire Resistance GRP gratings can be manufactured to meet fire safety standards, making them suitable for applications where fire risk is a concern. Depending on the resin used, GRP grating systems can achieve various fire ratings, providing an additional layer of safety in critical environments.

5. Low Maintenance GRP materials require minimal maintenance compared to traditional materials. Their non-corrosive nature means that they do not need regular painting or treatments, providing long-term cost savings and reducing the need for frequent inspections.

Applications of GRP Grating Systems

grp grating systems

The versatility of GRP grating systems means they can be used in a wide range of sectors, including

- Marine and Coastal Applications GRP grating is highly favored in marine environments for applications such as walkways, docks, and platforms due to its corrosion resistance and lightweight features.

- Chemical and Petrochemical Industries With their ability to withstand aggressive chemicals, GRP gratings are commonly used in tanks, platforms, and as walkways in chemical processing plants.

- Wastewater Treatment The durability and low maintenance of GRP gratings make them a suitable choice for wastewater treatment facilities, where exposure to corrosive substances is frequent.

- Industrial Flooring and Platforms GRP grating is increasingly used for industrial flooring, providing slip resistance and safety in factories, warehouses, and workshops.

- Infrastructure GRP grating systems are also employed in infrastructure projects, including bridges, tunnels, and stairways, where strength and lightweight features are desired.

Conclusion

In conclusion, GRP grating systems are an innovative solution for various industrial and commercial applications. Their exceptional corrosion resistance, lightweight design, high load capacity, durability, and low maintenance requirements make them an increasingly popular choice in numerous sectors. As industries continue to seek materials that provide long-lasting performance and safety, GRP grating systems will likely play a crucial role in meeting these demands moving forward.

Investing in GRP grating not only enhances operational efficiency but also contributes to the sustainability goals of many organizations by reducing the need for frequent replacements and maintenance. With an ever-expanding range of applications, the future of GRP grating systems looks promising, standing as a testament to the advancements in composite materials and engineering.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025