loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Advanced Grating Solutions for Enhanced Optical Performance and Efficiency

Understanding GRP Grating Systems A Comprehensive Overview

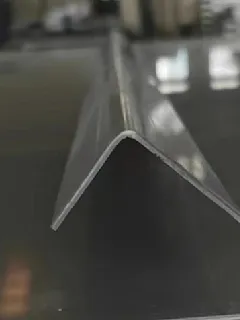

GRP (Glass Reinforced Plastic) grating systems have emerged as a leading choice in various industrial and commercial applications, owing to their unique combination of strength, durability, and lightweight properties. This innovative material combines fiberglass with resin, resulting in a robust product that can withstand harsh environmental conditions while providing excellent performance. This article explores the key features, benefits, applications, and installation considerations associated with GRP grating systems.

Key Features

One of the most defining features of GRP grating systems is their corrosion resistance. Unlike traditional steel grates, GRP is impervious to a wide range of chemicals and environmental factors, making it ideal for use in applications exposed to hazardous substances. This characteristic significantly extends the lifespan of the grating, reducing maintenance and replacement costs over time.

Additionally, GRP gratings are non-conductive, which enhances safety in environments where electrical hazards may be present. Their lightweight construction allows for easier handling and installation compared to heavier materials like steel or concrete, minimizing labor costs and facilitating quicker project completion.

Benefits of GRP Grating Systems

1. Durability GRP grating systems are designed to endure extreme weather conditions, UV exposure, and temperature fluctuations. This resilience means they can be used in a variety of environments, from offshore oil rigs to chemical processing plants.

2. Safety Many GRP gratings come with slip-resistant surfaces, which significantly reduce the risk of accidents in high-traffic areas. Moreover, their inherent non-conductivity makes them suitable for electrical installations.

3. Sustainability GRP materials are often produced using eco-friendly processes. Additionally, their long lifespan and low maintenance requirements contribute to lower overall environmental impact.

4. Versatility GRP grating systems can be customized to meet specific load-bearing requirements. They can be manufactured in various colors and sizes and can be used for flooring, walkways, trench covers, and even as architectural features.

grp grating systems

Applications

GRP grating systems are widely applicable across numerous industries. In the chemical and petrochemical sectors, they provide safe, reliable surfaces in processing areas where spills and chemical exposure are common. In water treatment facilities, their corrosion-resistant properties make them suitable for use in both wastewater and potable water applications.

The construction industry also benefits from GRP gratings, where they can be used in temporary walkways, scaffolding, and as part of structural components. Marine environments, such as docks and piers, capitalize on the material's resistance to saltwater and humidity, ensuring longevity in such challenging conditions.

Moreover, GRP grating systems are popular in food processing facilities, where cleanliness and hygiene are paramount. Their smooth surfaces and ease of cleaning make them an excellent choice for these environments, where traditional materials may harbor bacteria or other contaminants.

Installation Considerations

When it comes to the installation of GRP grating systems, several factors should be considered. First, it is essential to assess the specific load requirements of the intended application, as this will influence the type of grating selected. GRP gratings typically come in different thicknesses and load ratings, so choosing the right option is critical for performance and safety.

Additionally, proper ventilation during installation is important, as it helps in curing the resin correctly, ensuring optimal strength and stability. The use of suitable fixing methods, such as stainless steel brackets or clips, is also necessary to secure the gratings effectively.

Finally, while GRP gratings require less maintenance than other materials, periodic inspections are advised to ensure their performance over time. Regular checks can help identify any wear or damage that might occur due to excessive loading or environmental factors.

Conclusion

In conclusion, GRP grating systems represent a modern solution to many challenges faced in industrial and commercial settings. Their durability, safety, and versatility make them an invaluable asset across a wide range of applications. As industries increasingly look towards sustainable and efficient materials, GRP grating systems are poised to play a significant role in the future of construction and engineering, offering a combination of performance and practicality that is hard to match. Whether in chemical plants, wastewater facilities, or construction sites, GRP gratings stand out as a reliable and innovative choice for progress in various sectors.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025