loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

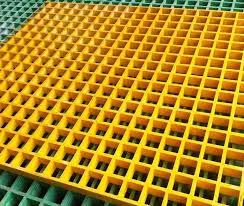

grp grating systems

Understanding GRP Grating Systems An Overview

GRP (Glass Reinforced Plastic) grating systems have become increasingly popular across various industries due to their unique properties and versatility. These systems, often referred to as fiberglass grating, are an excellent alternative to traditional materials like steel or wood. This article will delve into the composition, benefits, applications, and maintenance of GRP grating systems, providing a comprehensive overview of their importance in modern industry.

What is GRP Grating?

GRP grating is made from a polymer matrix reinforced with glass fibers, resulting in a lightweight yet incredibly strong product. The manufacturing process involves the pultrusion technique, where fiberglass strands are pulled through a resin bath and then cured to form a solid, durable panel. The resulting grating is non-corrosive, UV resistant, and has a high strength-to-weight ratio, making it ideal for various applications, particularly in harsh environments.

Benefits of GRP Grating Systems

1. Corrosion Resistance One of the most significant advantages of GRP grating is its resistance to corrosion. Unlike metal grates that can rust and deteriorate when exposed to moisture and chemicals, GRP grating remains stable and intact, significantly extending its lifespan.

2. Lightweight GRP grating is much lighter than traditional materials, which simplifies handling and installation. This feature can reduce labor costs and make it easier to transport and install in various settings.

3. Safety Many GRP grating products come with anti-slip surfaces, enhancing safety in areas where liquid spills or slippery conditions are common. The grating provides a secure footing, which is vital in industrial settings, walkways, and platforms.

4. Low Maintenance GRP grating requires minimal maintenance compared to traditional materials. It does not need regular painting or extensive upkeep, making it a cost-effective solution in the long run.

5. Versatility GRP grating is available in various colors, sizes, and designs, allowing for customization to fit specific applications. This flexibility means it can be used in everything from pedestrian walkways to heavy-duty industrial flooring.

6. Environmental Considerations The production of GRP grating often utilizes recycled materials, and its longevity reduces the need for replacement, minimizing waste. Additionally, GRP is energy efficient to manufacture, aligning with sustainability goals in many industries.

grp grating systems

Applications of GRP Grating Systems

GRP grating systems are utilized in diverse sectors due to their versatility and durability

. Some common applications include- Industrial Flooring GRP grating is widely used in factories and processing plants where there may be exposure to chemicals. Its corrosion resistance makes it ideal for such environments.

- Walkways and Platforms The lightweight and anti-slip properties of GRP grating make it suitable for pedestrian walkways, providing safety and ease of movement.

- Marine Applications In the marine industry, GRP grating is employed on docks and platforms due to its resistance to saltwater and marine environments.

- Water Treatment Plants The non-corrosive nature of GRP makes it a preferred choice for water treatment facilities where exposure to moisture and chemicals is prevalent.

Maintenance of GRP Grating Systems

Although GRP grating systems are low maintenance, periodic inspections are recommended to ensure their ongoing integrity. Cleaning can typically be accomplished with soap and water, and any damaged sections should be addressed promptly to maintain safety and functionality. Regular checks for signs of wear, especially in high-traffic areas, can help in early identification of potential issues.

Conclusion

GRP grating systems offer a robust, safe, and environmentally friendly solution for various industrial applications. Their unique properties, such as corrosion resistance and lightweight design, make them an invaluable choice in settings where traditional materials may falter. As industries continue to recognize the benefits of GRP grating, its adoption is expected to grow, solidifying its place as a modern engineering solution in challenging environments. Ultimately, the future of GRP grating systems looks promising as they meet the demands of safety, durability, and efficiency in various sectors.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025