loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

GRP Pultruded Grating Solutions - Durable and Lightweight

The Advantages of GRP Pultruded Grating

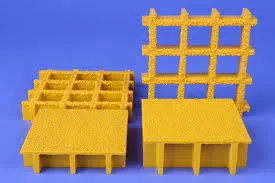

Glass Reinforced Plastic (GRP) pultruded grating is an innovative material that has gained significant attention in various industries due to its unique properties and advantages. This composite material is created through a pultrusion process, where glass fibers are impregnated with resin and pulled through a heated die to create strong, lightweight structural components. GRP pultruded grating is used extensively in applications such as walkways, platforms, and stair treads, owing to its numerous benefits.

The Advantages of GRP Pultruded Grating

Corrosion resistance is another significant benefit of GRP pultruded grating. Made from non-metallic materials, GRP does not rust or corrode like metals when exposed to harsh environments, including chemicals, seawater, and ultraviolet (UV) light. This durability extends the lifespan of the grating and decreases maintenance costs, making it an economical choice for industries like oil and gas, marine, and wastewater treatment.

grp pultruded grating

Moreover, GRP grating provides excellent slip resistance, which enhances safety in various settings. The surface of GRP grating can be designed with a textured finish, providing better traction, even in wet or slippery conditions. This makes it an ideal choice for flooring in areas where spills are common, such as kitchens, factories, and outdoor walkways.

Another important aspect to consider is the versatility of GRP pultruded grating. It can be easily manufactured in various sizes, colors, and load-bearing capacities to meet specific project requirements. This customization allows architects and engineers to meet aesthetic needs while ensuring that the structural demands are adequately addressed. Additionally, GRP can be molded into different forms, enabling the creation of unique shapes and designs that would be difficult to achieve with other materials.

Sustainability is becoming increasingly important in construction and industrial operations, and GRP grating is aligned with this trend. The materials used in GRP production can be sourced and disposed of in environmentally friendly ways, making it a more sustainable option compared to traditional metal grating. Furthermore, its longevity reduces the need for frequent replacements, thus minimizing waste over time.

In summary, GRP pultruded grating emerges as a superior alternative to traditional grating materials, owing to its lightweight nature, corrosion resistance, slip resistance, versatility, and sustainability. As industries continue to prioritize efficiency and safety, GRP grating is poised to play a crucial role in modern construction and manufacturing applications. Its advantages not only enhance operational effectiveness but also contribute to safer and more sustainable working environments.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025