loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Secure and Efficient Access to GRP Platforms

Exploring GRP Access Platforms Enhancing Safety and Efficiency in Construction

In recent years, the demand for innovative and safe access solutions in the construction industry has surged. One of the pivotal developments in this domain is the introduction and widespread adoption of GRP (Glass Reinforced Plastic) access platforms. These platforms offer a robust and versatile option for work at heights, ensuring safety, durability, and efficiency.

What is GRP?

GRP, or Glass Reinforced Plastic, is a composite material made from a polymer matrix reinforced with glass fibers. This combination yields a lightweight yet extremely strong structure that can withstand various environmental conditions. GRP is non-corrosive, UV-resistant, and requires minimal maintenance, making it ideal for outdoor and industrial applications.

Safety First

One of the primary advantages of GRP access platforms is their contribution to safety in construction and maintenance tasks. Traditional materials, such as metal, often pose risks of rust, corrosion, and electrical hazards. In contrast, GRP does not conduct electricity, reducing the risk of electrocution in sensitive environments. Furthermore, the slip-resistant surface of GRP platforms helps prevent falls, making them a preferred choice for workers who operate at height.

Versatility in Applications

GRP access platforms are highly versatile and can be customized for a range of applications. Whether it’s for construction sites, maintenance of electrical substations, or access to high industrial machinery, GRP platforms can be designed to fit specific needs. They can be made in various shapes and sizes, ensuring that companies can find the perfect match for their unique operational requirements.

grp access platforms

Lightweight and Easy to Transport

Another significant benefit of GRP is its lightweight nature. Compared to traditional materials like steel, GRP access platforms are easier to transport and maneuver, reducing logistical challenges on-site. This lightweight quality also allows for easier assembly and disassembly, thus saving time and labor costs during setup and takedown.

Environmental Considerations

As industries increasingly prioritize sustainability, GRP access platforms stand out as an environmentally friendly option. They can be manufactured from recycled materials and are fully recyclable at the end of their life cycle. Moreover, their longevity and durability mean fewer replacements are needed over time, which reduces waste and the consumption of resources.

Cost-Effectiveness

While the initial cost of GRP access platforms may be higher than traditional options, the long-term savings they offer are considerable. Their durability results in lower maintenance and replacement costs. Additionally, the safety features inherent in GRP designs can lead to decreased accident rates and associated costs, making them a wise investment for companies committed to worker safety and operational efficiency.

Conclusion

In conclusion, GRP access platforms represent a significant advancement in the construction industry’s approach to working at height. With their myriad safety features, versatility, light weight, and sustainability, these platforms address critical challenges faced by construction and maintenance teams. As the industry moves forward, the adoption of GRP solutions will likely continue to rise, leading to safer and more efficient work environments. The future of access solutions shines brightly with GRP at the forefront, paving the way for innovative practices in construction and beyond.

-

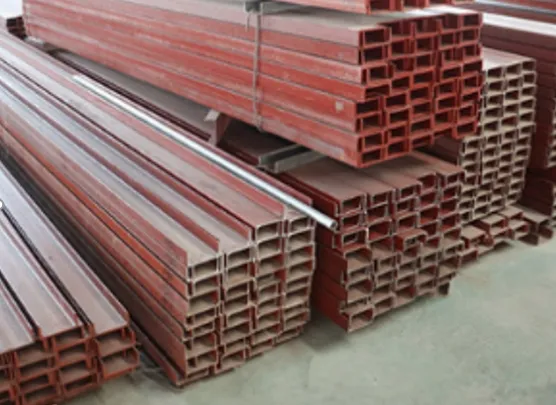

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025