loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

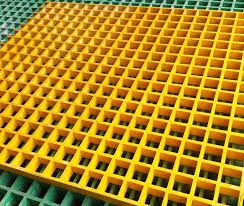

grating cover

Understanding Grating Cover A Comprehensive Overview

Grating covers, though often overlooked, play a crucial role in various industrial, commercial, and municipal sectors. These covers, typically made from materials like steel, fiberglass, or aluminum, serve as protective barriers while allowing drainage and ventilation. Their design and composition contribute to safety, durability, and functionality, making them essential elements in infrastructure.

Types of Grating Covers

Grating covers generally come in several types, each suited for different applications. The most common types include

1. Steel Grating Covers Known for their strength and load-bearing capacity, steel grating covers are prevalent in industrial settings. They are usually galvanized to prevent rust and corrosion, ensuring longevity even in harsh conditions.

2. Fiberglass Grating Covers Lightweight and resistant to chemicals, fiberglass grating covers are ideal for environments prone to corrosive substances. They offer excellent non-slip properties, making them suitable for wet and hazardous areas.

3. Aluminum Grating Covers These covers combine lightness with strength and are particularly favored in applications where weight is a concern. Aluminum grating covers are often used in pedestrian areas due to their aesthetic appeal and easy installation.

Importance of Grating Covers

Grating covers serve several essential functions in various settings

- Safety They provide a secure surface for pedestrian and vehicular traffic, reducing the risk of accidents. Properly designed grating covers can prevent slips and falls, especially in areas where water accumulation is common.

- Drainage Grating covers allow for effective water drainage, minimizing the risk of flooding and water damage. They enable water to flow through while trapping larger debris, ensuring effective drainage systems.

grating cover

- Ventilation In many applications, grating covers facilitate air flow, helping to maintain optimal conditions in environments like industrial plants, HVAC units, and beyond.

Design Considerations

When selecting grating covers, several design aspects must be considered to ensure effectiveness

- Load Rating It is crucial to choose a grating cover that can handle the anticipated load. Different applications require different load capacities, so it's important to assess the specific needs of each environment.

- Material Selection The material used for grating covers should be chosen based on environmental conditions, weight requirements, and potential exposure to chemicals. For example, marine applications may necessitate corrosion-resistant materials.

- Safety Features Non-slip surfaces, beveled edges, and high-visibility colors can enhance the safety of grating covers. Ensuring these features are included in the design is essential, particularly in public areas.

Installation and Maintenance

Proper installation of grating covers is vital to their performance and longevity. They should be securely fastened to prevent movement or uplift, especially in high-traffic areas. Regular maintenance, including inspections for damage or wear, is also necessary to ensure that they remain functional. Cleaning grating covers periodically helps maintain their effectiveness, particularly in drainage applications where debris could impede flow.

Conclusion

Grating covers may seem like small components in the grand scheme of infrastructure, but their importance cannot be overstated. From providing safety to facilitating drainage and ventilation, these covers are integral to various applications. When selecting and installing grating covers, careful consideration of type, material, design features, and maintenance will ensure they serve their intended purpose effectively. As industries continue to evolve, the demand for reliable and durable grating covers will undoubtedly persist, highlighting their significance in our daily lives.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025