loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Structure of Fiber-Reinforced Polymer Composites for Enhanced Performance and Durability

Glass Reinforced Plastic Structures An Overview

Glass Reinforced Plastic (GRP), also known as Fiberglass Reinforced Plastic (FRP), is a composite material made from a polymer matrix reinforced with glass fibers. This combination results in an innovative structure with enhanced properties, making it widely used in various industries such as construction, automotive, aerospace, and marine applications. The development and application of GRP structures have garnered significant attention due to their unique characteristics that offer numerous benefits over traditional materials.

Composition and Manufacturing

The primary components of Glass Reinforced Plastic include a thermosetting resin—commonly polyester, vinylester, or epoxy—and glass fibers. The manufacturing process typically involves the layering of glass fibers in a resin matrix, which is then cured to form a solid structure. There are various fabrication techniques, including hand lay-up, spray-up, and filament winding, each offering different attributes suitable for specific applications. The versatility in manufacturing allows for the creation of complex shapes and designs that would be challenging or impossible to achieve with conventional materials like metal or concrete.

Advantages of GRP Structures

1. Lightweight One of the most notable advantages of GRP is its low weight compared to traditional materials. This property is crucial for sectors like aerospace and automotive, where weight reduction can lead to improved fuel efficiency and performance.

2. Corrosion Resistance GRP is inherently resistant to corrosion, making it ideal for use in harsh environments, including chemical processing plants, marine applications, and wastewater facilities. This characteristic significantly extends the lifespan of structures and reduces maintenance costs.

3. High Strength-to-Weight Ratio The reinforcing glass fibers provide strength and rigidity, allowing GRP structures to withstand significant loads while remaining lightweight. This feature is particularly beneficial in applications such as bridge construction or wind turbine blades, where strength and flexibility are critical.

4. Thermal and Electrical Insulation GRP offers excellent thermal and electrical insulation properties, making it suitable for applications in electrical enclosures, aerospace components, and building materials where temperature control is essential.

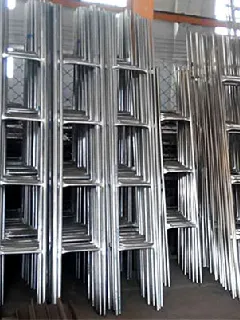

glass reinforced plastic structure

5. Design Flexibility The ability to mold GRP into various shapes and sizes allows architects and engineers to realize innovative designs without the restrictions imposed by traditional materials. This flexibility enhances aesthetic appeal and functional performance in architectural applications.

Applications of GRP Structures

GRP structures find extensive applications across multiple industries. In the construction sector, they are used for cladding, roofing, and even entire building frames, providing a modern alternative to concrete and steel. GRP's lightweight and corrosion-resistant nature makes it particularly advantageous for coastal and marine infrastructure, such as docks, piers, and pilings.

In the automotive industry, GRP is frequently used in the manufacture of body panels, interior components, and structural elements, contributing to the overall lightweight design of vehicles. Similarly, in the aerospace sector, GRP is used for fuselage components and wing structures, where reducing weight without compromising strength is paramount.

The energy sector also benefits from GRP, particularly in wind turbine blades, where the material's strength and lightweight properties contribute to improved energy efficiency and performance. Additionally, GRP is utilized in structural components for oil and gas exploration, ensuring durability in extreme conditions.

Future Prospects and Considerations

As industries continue to seek materials that balance performance, cost, and environmental impact, the demand for Glass Reinforced Plastic structures is expected to grow. Innovations in recycling and sustainability processes may further enhance GRP's appeal, addressing concerns about plastic waste and environmental stewardship. Moreover, ongoing research into enhancing the properties of GRP, such as improving impact resistance or fire performance, will likely expand its application horizons.

In conclusion, Glass Reinforced Plastic structures represent a significant advancement in materials science, offering unique benefits that cater to the demands of modern industries. With continued innovations and a focus on sustainability, GRP is poised to play an increasingly crucial role in the development of durable, lightweight, and versatile structures. The future of GRP looks bright, providing endless opportunities for creativity and functionality across various sectors.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025