loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Advantages of Glass Fiber Reinforced Polymer Rebar in Construction and Infrastructure Applications

Glass Fiber Reinforced Polymer (GFRP) Rebar Revolutionizing Construction Materials

In the ever-evolving field of construction, the search for innovative, sustainable, and durable materials is ongoing. One of the most significant advancements in this area is the development of glass fiber reinforced polymer (GFRP) rebar. This material has gained attention for its unique properties, such as high strength-to-weight ratio, corrosion resistance, and non-magnetic characteristics, making it a viable alternative to traditional steel rebar in various construction applications.

Understanding GFRP Rebar

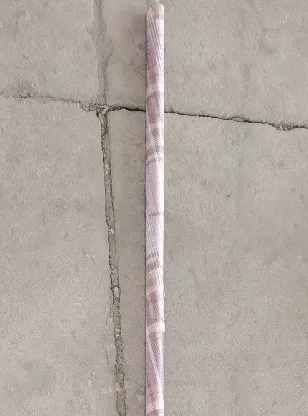

GFRP rebar is composed of a polymer matrix reinforced with glass fibers. The glass fibers provide strength and structural integrity, while the polymer matrix offers protection against environmental degradation. The manufacturing process involves winding glass fibers around a mandrel, which is then coated with a resin. This results in a lightweight, yet robust rebar that can be produced in various diameters and lengths to meet specific project requirements.

Advantages of GFRP Rebar

1. Corrosion Resistance One of the principal advantages of GFRP rebar is its exceptional resistance to corrosion. Unlike steel, which is prone to rust when exposed to moisture and chemicals, GFRP rebar remains unaffected by these elements. This characteristic significantly enhances the longevity of structures, particularly in harsh environments such as marine settings or areas with high de-icing salt usage.

2. High Strength-to-Weight Ratio GFRP rebar is significantly lighter than its steel counterpart, with a weight reduction of up to 75%. This reduction in weight not only makes handling and installation easier but also reduces transportation costs. Moreover, GFRP exhibits high tensile strength, which ensures that structures built using this material can withstand substantial loads.

3. Non-Magnetic and Non-Conductive The non-magnetic properties of GFRP rebar make it an ideal choice for applications in sensitive environments, such as hospitals and laboratories, where electromagnetic interference must be minimized. Additionally, its non-conductive nature reduces the risk of electrical hazards and makes it suitable for use in structures where electrical applications are present.

glass fiber reinforced polymer gfrp rebar

4. Thermal Insulation GFRP’s thermal insulation properties contribute to energy savings in buildings. By reducing thermal bridging, GFRP rebar can help maintain stable indoor temperatures, leading to reduced heating and cooling costs.

Applications of GFRP Rebar

The applications of GFRP rebar extend across various sectors. In civil engineering, it is used in bridge decks, parking structures, and waterfront structures where corrosion resistance is critical. In buildings, GFRP can be used in columns, beams, and slabs, providing strength without adding significant weight. Its use in precast concrete products is also becoming increasingly common, as manufacturers seek to enhance the durability and longevity of their products.

Challenges and Considerations

Despite its many advantages, there are challenges associated with the adoption of GFRP rebar. Initially, the cost of GFRP can be higher than that of traditional steel rebar. However, considering the long-term benefits—such as reduced maintenance costs and increased durability—many industry experts argue that GFRP rebar is a worthwhile investment. Additionally, GFRP lacks the established standards and codes that govern steel rebar, which presents a barrier to its widespread acceptance in some regions.

Conclusion

As the construction industry continues to innovate and adapt to changing environmental and economic demands, GFRP rebar stands out as a promising alternative to traditional materials. Its combination of strength, durability, and resistance to environmental factors positions it as a key player in sustainable construction practices. By investing in education and addressing the hurdles associated with its use, the construction industry can further harness the advantages of GFRP rebar, paving the way for more resilient and environmentally friendly infrastructure. Embracing GFRP technology not only enhances the performance of structures but also contributes to a greener and more sustainable future in construction.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025