loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

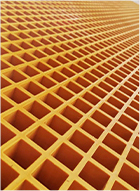

glass reinforced plastic structure

Understanding Glass Reinforced Plastic Structures

Glass Reinforced Plastic (GRP), often referred to as fiberglass, is a composite material made from a polymer matrix reinforced with glass fibers. This advanced material showcases a unique combination of properties that makes it highly suitable for a variety of structural applications. The increasing demand for lightweight yet durable materials has propelled GRP to the forefront of numerous industries, including construction, automotive, aerospace, and marine engineering.

Understanding Glass Reinforced Plastic Structures

Moreover, GRP is inherently resistant to corrosion and environmental degradation. Unlike traditional materials like steel or aluminum, fiberglass does not rust or corrode when exposed to moisture or chemicals. This makes GRP an ideal choice for structures that are exposed to harsh settings, such as bridges, storage tanks, and pipelines, significantly extending their lifespan and reducing maintenance costs.

glass reinforced plastic structure

The versatility of GRP also extends to its manufacturing processes, which can be tailored to achieve various shapes and sizes. Techniques such as hand lay-up, spray-up, and pultrusion allow for the production of complex geometries, making it possible to create customized components that meet specific design requirements. This adaptability is a key factor in the material’s appeal across different sectors, enabling designers and engineers to innovate without being constrained by material limitations.

In addition to its mechanical properties, GRP offers excellent thermal and acoustic insulation. The non-conductive nature of fiberglass makes it a suitable choice for applications that require insulation from heat or noise, contributing to energy efficiency and comfort in buildings and vehicles.

However, the manufacturing of GRP does present environmental challenges. The production process can generate hazardous waste and VOC emissions, necessitating the adoption of more sustainable practices. Recently, the industry has made strides in developing eco-friendly resins and recycling methods to mitigate these concerns.

In conclusion, Glass Reinforced Plastic structures represent a significant advancement in material science, offering strength, durability, and versatility across various applications. While challenges remain in terms of environmental impact, the ongoing development of sustainable manufacturing practices holds promise for the future of GRP. As industries continue to seek innovative solutions for their structural needs, GRP is well-positioned to play a pivotal role in the evolution of modern engineering.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025