loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Glass Fiber Reinforced Polymer Bars - Superior Strength and Durability

Glass Fiber Reinforced Polymer Bars Revolutionizing Construction and Engineering

In the ever-evolving landscape of construction and engineering materials, Glass Fiber Reinforced Polymer (GFRP) bars are emerging as a remarkable innovation. Known for their exceptional strength-to-weight ratio, corrosion resistance, and flexibility, GFRP bars are transforming traditional building practices and offering new solutions to engineering challenges.

Composition and Properties

GFRP bars consist of a polymer matrix reinforced with glass fibers, providing a unique combination of properties that set them apart from conventional steel reinforcement bars. The glass fibers are embedded in a resin matrix, which can be tailored to achieve specific performance characteristics. This composite material exhibits a tensile strength that is comparable to, or even surpasses, that of steel, while being significantly lighter. This lightweight nature allows for easier handling and installation, reducing labor costs and construction time.

Another striking feature of GFRP bars is their resistance to chemical corrosion. Unlike steel, which is prone to rusting and degradation when exposed to moisture and harsh chemicals, GFRP bars maintain their integrity in aggressive environments. This makes them an ideal choice for use in coastal regions, chemical plants, bridges, and other structures where traditional materials may fail over time.

Applications in Engineering and Construction

The use of GFRP bars is rapidly gaining ground in various sectors of construction and engineering. Their application spans reinforced concrete structures, such as bridges, parking garages, and highway systems, where they provide superior durability and longevity. GFRP bars can also be utilized in precast concrete elements, which are manufactured in controlled environments, offering enhanced quality and consistency in construction.

glass fiber reinforced polymer bars

Furthermore, GFRP bars are being integrated into infrastructure rehabilitation projects. As many existing structures are aging and in need of reinforcement, GFRP provides a non-invasive solution that can extend their lifespan without compromising structural integrity. This is particularly beneficial in retrofitting applications, where the addition of traditional steel reinforcement can significantly increase the weight of the structure.

Sustainability and Environmental Impact

In today’s world, the push for sustainable construction practices is more critical than ever. GFRP bars align with this goal by offering a longer-lasting alternative to traditional materials. Their resistance to corrosion reduces the need for frequent repairs or replacements, leading to lower maintenance costs and decreased material waste over time. Additionally, the lightweight nature of GFRP contributes to lower energy consumption during transportation and installation.

Moreover, the production of GFRP materials can be optimized to minimize environmental impact. By employing advanced manufacturing techniques, it is possible to utilize recycled glass fibers and eco-friendly resins, further enhancing the sustainable profile of GFRP bars.

Conclusion

As construction and engineering continue to advance, the integration of Glass Fiber Reinforced Polymer bars is positioned to play a pivotal role. With their superior mechanical properties, resistance to environmental factors, and alignment with sustainable practices, GFRP bars offer a modern solution to age-old challenges in building and infrastructure projects. From bridges to high-rise buildings, the potential applications are vast, making GFRP bars not just a trend, but a transformative material in the construction industry. As awareness and adoption of GFRP continue to grow, we can expect to see a significant shift in how engineers and builders approach the challenges of modern construction.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

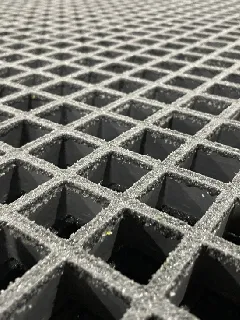

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025