loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

galvanized storage tank

The Importance of Galvanized Storage Tanks in Modern Industry

In the realm of modern industrial applications, the need for reliable and durable storage solutions is paramount. Among these, galvanized storage tanks stand out as a preferred option for many businesses. These tanks are essentially made from steel that has been coated with a layer of zinc, which provides enhanced protection against corrosion and degradation. This article aims to explore the importance, benefits, and applications of galvanized storage tanks in various industries.

Corrosion Resistance and Longevity

One of the main advantages of galvanized storage tanks is their exceptional resistance to corrosion. This characteristic is particularly crucial for industries that deal with liquids prone to cause rust, such as water, chemicals, and oils. The galvanization process involves dipping the steel in molten zinc, where the zinc forms a protective barrier that shields the underlying metal from moisture and environmental factors. As a result, galvanized tanks can last for decades, significantly reducing the need for frequent replacements and maintenance. This longevity translates into cost savings for businesses, making them an economically viable choice.

Versatility in Applications

The versatility of galvanized storage tanks cannot be overstated. They can be used in various applications across multiple industries, including agriculture, construction, food and beverage, wastewater treatment, and more. In agriculture, for instance, these tanks are often utilized for storing water, feed, and even fertilizers. The food and beverage industry also benefits from galvanized tanks as they provide safe storage for ingredients and liquids, maintaining their quality over time. Furthermore, their strength and sturdiness make them ideal for construction sites where they might be used for storing materials or water supply.

Environmental Impact and Sustainability

galvanized storage tank

As industries increasingly focus on sustainability, galvanized storage tanks offer an environmentally friendly option. Their ability to resist corrosion means they need fewer replacement cycles, reducing waste and the consumption of new materials. Additionally, the use of zinc in the galvanization process is beneficial because zinc is a naturally occurring mineral that is recyclable. When a galvanized tank does reach the end of its lifespan, its components can be repurposed, further minimizing the overall environmental impact.

Ease of Installation and Customization

Another compelling aspect of galvanized storage tanks is their ease of installation. They come in various shapes and sizes, allowing for tailored solutions based on specific storage needs. Whether it’s a large tank for industrial purposes or a smaller one for agricultural use, galvanized tanks can be manufactured to meet required specifications. Their lightweight nature compared to other storage solutions also makes them easier to transport and install, which can be a considerable advantage in project timelines.

Safety and Compliance

Safety is a primary concern in any industrial setting. Galvanized storage tanks are designed with safety features that prevent leaks and spills, thereby protecting the surrounding environment and maintaining compliance with regulatory standards. Many industries are required to adhere to strict guidelines regarding the storage of hazardous materials, and galvanized tanks often meet or exceed these requirements, providing peace of mind to business owners and operators.

Conclusion

Galvanized storage tanks play a vital role in various industries by offering durable, versatile, and sustainable storage solutions. Their resistance to corrosion, ease of installation, and compliance with safety regulations make them an ideal choice for businesses looking to optimize their operations. As industries continue to evolve and seek more efficient solutions, the importance of galvanized storage tanks will likely only increase, solidifying their place in the landscape of modern storage solutions.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

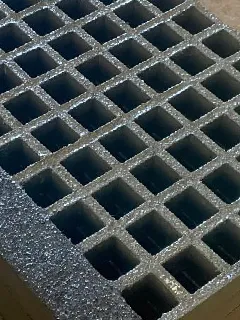

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025