loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

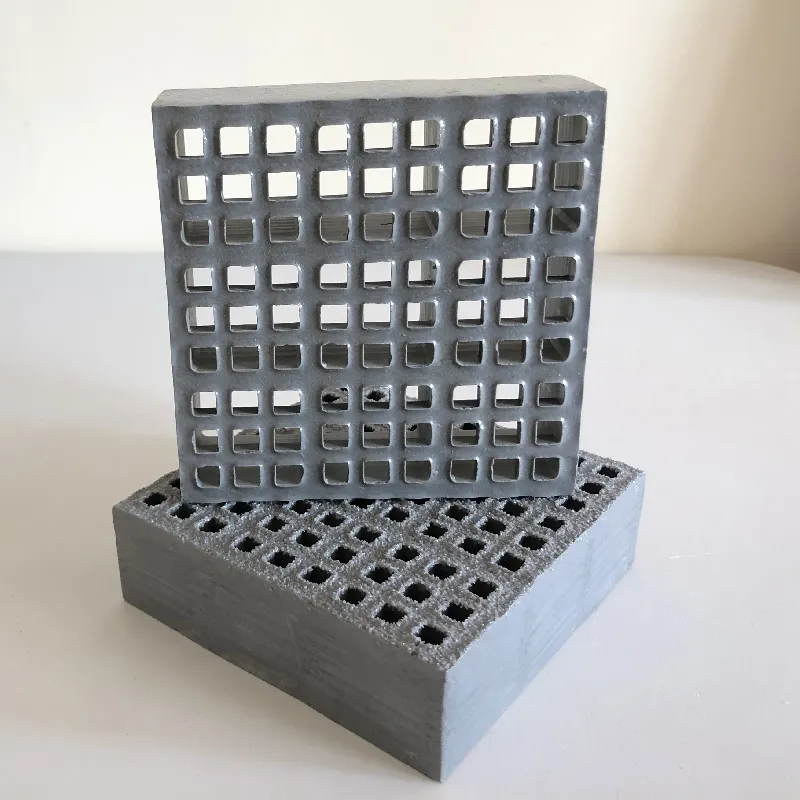

Durable Galvanized Steel Bar Grating for Versatile Applications and Improved Safety Solutions

The Benefits and Applications of Galvanized Bar Grating

Galvanized bar grating is a versatile, durable, and economical solution widely used in various industrial and architectural applications. It is made from steel bars that are welded together to form a grid-like structure, which is then coated with a layer of zinc to enhance its corrosion resistance. This process of galvanization not only prolongs the lifespan of the grating but also makes it ideal for use in harsh environments where exposure to moisture, chemicals, and high traffic can lead to deterioration.

Advantages of Galvanized Bar Grating

1. Corrosion Resistance One of the standout features of galvanized bar grating is its ability to withstand corrosion. The galvanization process creates a protective barrier between the steel and the environment, preventing rust and corrosion. This makes galvanized grating suitable for applications in coastal environments, wastewater treatment plants, and chemical processing facilities where exposure to harsh elements is common.

2. Strength and Durability Galvanized bar grating exhibits exceptional strength, making it capable of supporting heavy loads. The welded design ensures that the grating maintains its integrity under pressure, making it a reliable flooring solution for walkways, platforms, and industrial equipment. Its durability also translates into lower maintenance costs over time, as it requires minimal upkeep compared to other materials.

3. Slip Resistance Safety is a critical factor in any industrial setting, and galvanized bar grating provides excellent slip resistance. The open design allows for effective drainage, reducing the risk of water pooling and creating slippery surfaces. Additionally, many manufacturers offer grating with serrated surfaces or additional coatings that further enhance slip resistance, making it suitable for wet or oily conditions.

4. Versatility Galvanized bar grating comes in a variety of styles, sizes, and configurations, allowing it to be used in a multitude of applications. It can be used as flooring in factories, as stair treads, trench covers, or even as decorative elements in architectural designs. Its versatility extends to various industries, including manufacturing, construction, agriculture, and transportation.

5. Cost-Effectiveness When considering both initial investment and long-term maintenance costs, galvanized bar grating proves to be a cost-effective choice. The durability and corrosion resistance reduce the need for frequent replacements or repairs, allowing businesses to allocate their resources more efficiently.

galvanized bar grating

Applications of Galvanized Bar Grating

1. Industrial Facilities In warehouses and factories, galvanized bar grating is often used for flooring systems that allow for easy movement of personnel and equipment. Its strength can support heavy machinery while its open design facilitates airflow and prevents the accumulation of debris.

2. Wastewater Treatment In wastewater treatment plants, galvanized bar grating is essential for walkways and catwalks over treatment tanks. Its corrosion resistance is particularly valuable in areas with high humidity and potential exposure to corrosive substances.

3. Construction In construction sites, galvanized bar grating serves as temporary flooring or fall protection for elevated work areas. Its lightweight yet strong material makes it easy to transport and install.

4. Transportation and Infrastructure Galvanized bar grating is commonly used in bridges and overpasses as walkways or protective barriers. It can also be found in railway applications, providing safe passage for workers and maintenance crews.

5. Architectural Use Beyond industrial applications, galvanized bar grating is increasingly being incorporated into architectural designs. It provides an aesthetic appeal and functionality in parks, outdoor venues, and modern buildings, where it can be used for railings, grilles, and decorative features.

Conclusion

In conclusion, galvanized bar grating is a highly advantageous material that combines strength, durability, and versatility. Its wide range of applications across various industries, coupled with its corrosion resistance and safety features, make it an indispensable asset for many projects. As industries continue to seek efficient and sustainable solutions, the demand for galvanized bar grating is expected to grow, solidifying its position as a critical component in modern infrastructure. Whether for industrial use or architectural innovation, galvanized bar grating remains a top choice for professionals aiming to achieve quality and longevity in their projects.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025