loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

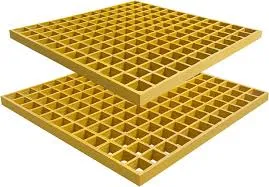

Corrosion-Resistant Steel Bar Grating for Enhanced Safety and Durability in Construction

The Versatility and Applications of Galvanized Bar Grating

Galvanized bar grating has become a cornerstone in various industries due to its durability, versatility, and aesthetic appeal. It consists of a series of parallel bars that are welded together, creating a strong and open grid structure. The galvanized refers to the hot-dip galvanization process it undergoes, where the steel is coated with zinc to enhance its corrosion resistance. This treatment allows the grating to withstand harsh environmental conditions, making it an ideal choice for numerous applications.

Key Advantages of Galvanized Bar Grating

One of the primary advantages of galvanized bar grating is its exceptional strength-to-weight ratio. This structural efficiency means that it can carry heavy loads while remaining lightweight and easy to handle. Consequently, it is frequently employed in construction, industry, and civil engineering. Additionally, the open design of bar grating allows for excellent drainage and ventilation, making it suitable for areas that require fluid flow or air passage.

Another significant benefit is its low maintenance requirement. Unlike traditional flooring systems that may require regular upkeep, galvanized bar grating is resistant to rust and corrosion, thereby reducing the need for repairs and replacements over its lifespan. This quality is especially crucial in industrial settings where downtime can be costly.

Applications of Galvanized Bar Grating

The versatility of galvanized bar grating makes it applicable in a wide range of sectors. In industrial environments, it is often utilized as flooring in processing plants, walkways, and platforms. The slip-resistant surface ensures safety for workers, even in wet or oily conditions. Furthermore, its strength allows heavy machinery and equipment to operate without significant strain on the grating itself.

galvanized bar grating

In commercial settings, galvanized bar grating can be found in shopping centers, airports, and other high-traffic areas where durability and maintenance are essential. Its aesthetic appeal is also noteworthy; the clean lines of the grating contribute to a modern look, which is increasingly desirable in contemporary architecture.

Another important application is in the construction of stair treads and landings. The open spaces allow for safe transportation of materials while minimizing the risks of slipping. The galvanized finish also ensures longevity and safety, as it prevents the accumulation of debris and moisture that could lead to accidents.

Environmental Benefits

In recent years, sustainability has become a significant concern across various industries. Galvanized bar grating plays a role in eco-friendly practices as it is manufactured from recyclable materials. Moreover, its longevity reduces the need for replacements, thereby conserving resources and energy. The production process for galvanized steel also has a lower environmental impact compared to other materials when considering the entire lifecycle from production to disposal.

Conclusion

In summary, galvanized bar grating stands out for its vital attributes and applications across multiple domains. The combination of strength, durability, and low maintenance makes it an ideal choice for both industrial and commercial purposes. Its ability to facilitate safety while providing functional and aesthetic benefits cannot be overstated. As industries continue to evolve and the demand for sustainable solutions grows, galvanized bar grating will undoubtedly remain a preferred option, providing effective, long-lasting solutions in a diverse range of settings. Ultimately, whether for construction, manufacturing, or architectural applications, the significance of galvanized bar grating in modern infrastructure cannot be overlooked.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025