loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

galvanized floor grating

Galvanized Floor Grating A Durable Choice for Industrial Applications

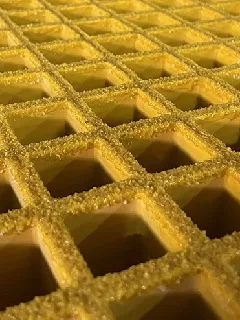

In the realm of industrial flooring solutions, galvanized floor grating has emerged as a popular choice due to its durability, safety features, and versatile applications. This type of flooring consists of a series of parallel metal bars or plates, typically made from steel, that are welded together at regular intervals to form a grid-like structure. The galvanization process, in which the steel is coated with a protective layer of zinc, enhances the material's resistance to corrosion and rust. This article delves into the benefits and applications of galvanized floor grating, highlighting why it is a reliable option for various environments.

One of the primary advantages of galvanized floor grating is its exceptional durability. Industrial settings often expose flooring to heavy foot traffic, machinery, and harsh chemicals. Galvanized grating is engineered to withstand these demanding conditions without succumbing to wear and tear. The zinc coating not only protects against moisture but also provides a barrier against chemicals that could otherwise degrade the steel. This longevity translates to lower maintenance costs and a longer service life, making it a cost-effective flooring option in the long run.

In addition to its durability, galvanized floor grating offers significant safety benefits. The open-grid design promotes excellent drainage, minimizing the risk of slipping in wet or oily conditions. Moreover, the grating is often designed with anti-slip surfaces to provide additional traction, making it a preferred flooring choice in applications where safety is paramount. Whether in factories, warehouses, or outdoor walkways, galvanized floor grating helps maintain a secure environment for workers and visitors alike.

galvanized floor grating

Versatility is another hallmark of galvanized floor grating. It can be fabricated in various sizes, thicknesses, and shapes to accommodate a wide range of applications. From platforms and staircases to walkways and trenches, this flooring solution can be customized to meet specific project requirements. Additionally, it is available in different styles, such as bar grating and expanded metal grating, allowing for further aesthetic and functional options. This adaptability makes it suitable for diverse industries, including manufacturing, construction, and wastewater treatment.

Furthermore, galvanized floor grating is an environmentally friendly choice. The process of galvanization itself is designed to be sustainable; the zinc coating prolongs the life of the metal, reducing the frequency of replacement and the waste associated with it. Additionally, as a recyclable material, galvanized steel contributes to a circular economy, aligning with modern sustainability goals.

In conclusion, galvanized floor grating stands out as a reliable, durable, and safe flooring solution for industrial applications. Its resistance to corrosion, slip prevention features, and versatility make it an ideal choice for various environments, from factories to outdoor walkways. By investing in galvanized floor grating, businesses can enhance safety, reduce maintenance costs, and contribute to a more sustainable future. As industries continue to evolve, the demand for resilient and efficient flooring solutions like galvanized grating is likely to grow, further solidifying its place in modern industrial design.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025