loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Design and Analysis of FRP Vessel Utilizing Multiport Valve Technology for Enhanced Efficiency

FRP Vessels with Multiport Valves A Comprehensive Overview

Fiber-Reinforced Plastic (FRP) vessels have gained significant importance in various industrial applications due to their lightweight properties, corrosion resistance, and ease of maintenance. When combined with multiport valves, FRP vessels offer enhanced operational efficiency, versatility, and reliability, making them an ideal choice for many processes in the chemical, water treatment, and food industries.

Understanding FRP Vessels

FRP vessels are constructed from a composite material that combines fiberglass with a polymer matrix. This composition gives them several advantages over traditional materials like metal. The corrosion-resistant nature of FRP makes it suitable for storing a wide range of chemicals, including acids, bases, and various solvents. These vessels can be fabricated in different shapes and sizes to meet the specific needs of various applications.

One of the key attributes of FRP is its lightweight nature. This property allows for easier transportation and installation, reducing overall project costs. Moreover, the flexibility in design enables manufacturers to create vessels that can withstand high pressures and temperatures, broadening their application scope.

The Role of Multiport Valves

Multiport valves are critical components in fluid management systems. These devices facilitate the efficient control of fluid flow through various pathways, providing versatility in application without the need for multiple conventional valves. A multiport valve typically features several inlet and outlet ports, allowing operators to redirect fluids as required.

Combining multiport valves with FRP vessels brings substantial benefits. For instance, in water treatment processes, a multiport valve can manage the flow of water between different filtration systems or storage tanks, optimizing the overall efficiency of the operation. This capability reduces the need for additional piping and fittings, which can be costly and time-consuming to install.

Enhanced Operational Efficiency

frp vessel with multiport valve

The integration of FRP vessels and multiport valves results in streamlined operations. By utilizing multiport valves, operators can easily switch between different processes, such as backwashing, rinsing, or chemical dosing, with minimal disruption. This feature is particularly beneficial in industries that require frequent changes in fluid management, such as reverse osmosis systems in water purification or chemical manufacturing.

Furthermore, the design of multiport valves often allows for automated control. Automation minimizes human error, ensuring consistent operation and reducing labor costs. This automated approach also enables remote monitoring, allowing operators to manage systems from a centralized control room, thereby enhancing safety and efficiency.

Environmental and Safety Considerations

The combination of FRP vessels and multiport valves is also beneficial from an environmental and safety standpoint. FRP materials are less prone to leaks and ruptures compared to traditional materials, reducing the risk of hazardous spills. Multiport valves offer a fail-safe mechanism, often including features such as pressure relief systems that protect against over-pressurization, enhancing overall system safety.

In industries where chemicals are handled, the reduced risk of corrosion and the robustness of FRP vessels contribute to a lower environmental impact. Fewer leaks mean less contamination of surrounding areas, aligning with regulatory standards and promoting sustainability.

Conclusion

The combination of FRP vessels with multiport valves represents a significant advancement in fluid management technology. The lightweight, corrosion-resistant properties of FRP, coupled with the operational versatility of multiport valves, create a synergistic effect that enhances efficiency, safety, and environmental compliance in various industrial applications. As industries continue to evolve and seek more sustainable practices, the adoption of these innovative technologies is likely to expand, paving the way for improved process management and optimized resource utilization.

In summary, the incorporation of FRP vessels paired with multiport valves is not just a trend but a necessary evolution in multiple fields ranging from water treatment to chemical processing, underscoring the ongoing commitment to innovation and efficiency in industrial practices.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

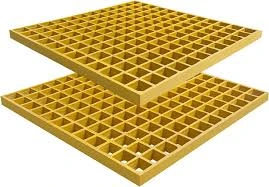

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025