loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp vessels

The Evolution and Applications of FRP Vessels

Fiberglass-reinforced plastic (FRP) vessels have gained significant traction in various industries due to their unique properties and advantages over traditional materials. These vessels, crafted from a composite of fiberglass and resin, possess a remarkable strength-to-weight ratio, resistance to corrosion, and flexibility in design. Their applications span a wide range of sectors, including chemical processing, water treatment, and food and beverage production.

The Evolution and Applications of FRP Vessels

Another significant benefit of FRP technology is its lightweight nature, which can greatly reduce transportation and installation costs. The reduced weight of FRP vessels allows for easier handling during manufacturing, transportation, and installation. In facilities where weight is a critical factor, such as offshore platforms and remote locations, the use of FRP can lead to substantial logistical advantages.

frp vessels

The versatility in the design of FRP vessels also deserves mention. These vessels can be molded into intricate shapes and sizes, allowing manufacturers to tailor them to specific requirements. This design flexibility opens avenues for customization that traditional materials cannot offer. Whether it’s for storage tanks, pressure vessels, or piping systems, FRP technology enables companies to meet the exact specifications needed for their applications.

In the water treatment industry, FRP vessels are particularly noted for their use in filtration systems and storage tanks. Their ability to resist algae growth and chemical leaching ensures that the quality of treated water is maintained. Furthermore, FRP's insulative properties help in maintaining appropriate temperatures for various processes, encouraging efficiency in energy use.

Moreover, the environmental advantages of using FRP should not be overlooked. As industries strive to minimize their environmental footprint, FRP vessels offer a sustainable solution. They are often manufactured using environmentally friendly processes, and their long lifespan reduces the need for frequent replacements.

As technology advances, the future of FRP vessels looks promising. Innovations in resin technology and manufacturing processes are expected to enhance their performance, making them even more appealing to various sectors. In conclusion, the evolution of FRP vessels illustrates a shift towards more sustainable, durable, and efficient solutions in industrial applications, making them a vital part of modern engineering and manufacturing landscapes.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

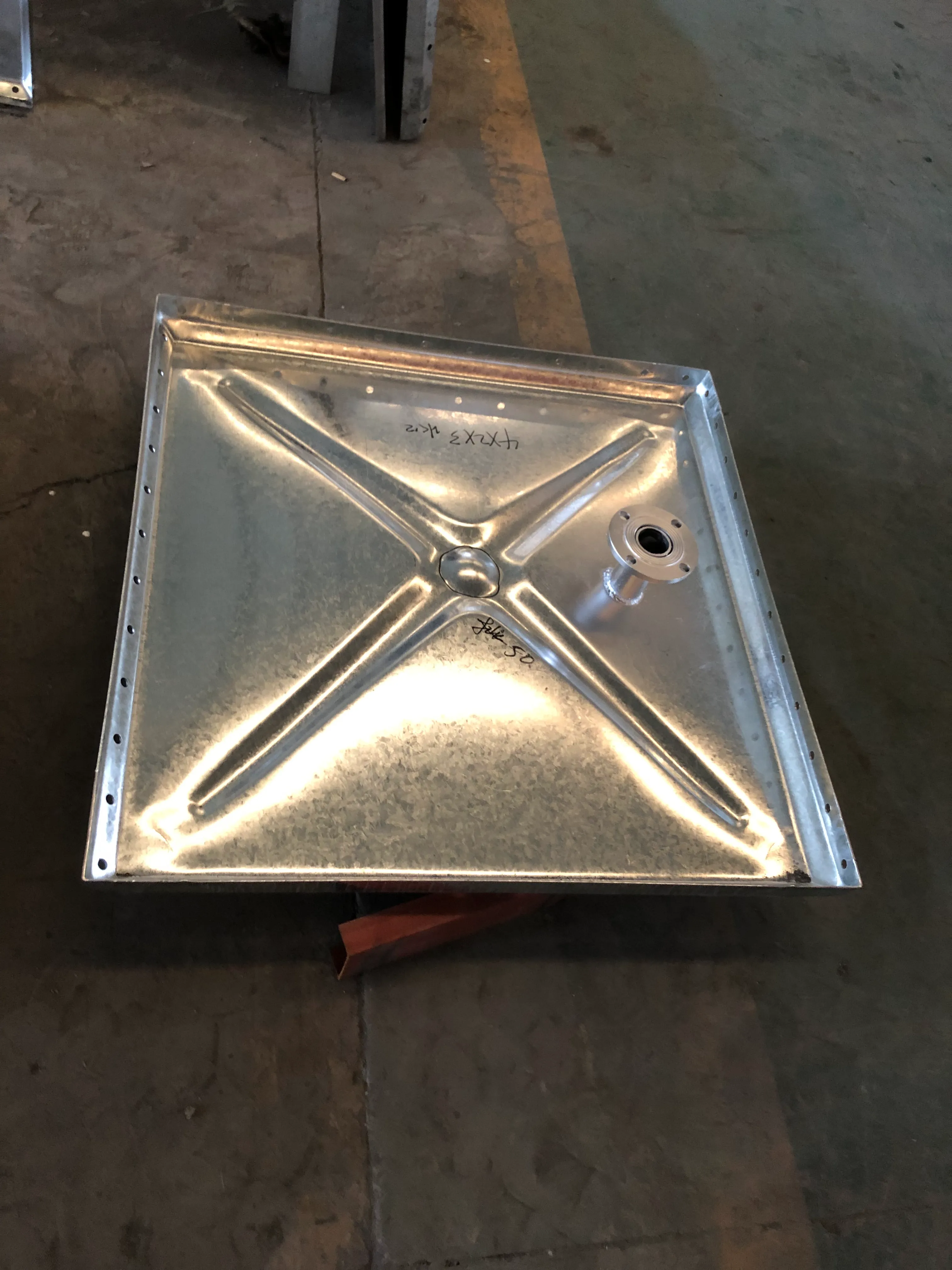

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025