loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Pricing Trends for FRP Vessels in Today's Market Analysis and Insights

Understanding FRP Vessel Prices Factors and Trends

Fiber Reinforced Plastic (FRP) vessels have revolutionized the design and production of containers, tanks, and other storage solutions in various industries, including chemical, marine, and wastewater management. Their lightweight nature, corrosion resistance, and customization capabilities have made them a preferred choice over traditional materials such as metal and concrete. However, the pricing of FRP vessels can vary significantly based on several factors. In this article, we will explore the key elements that influence FRP vessel prices and highlight the current trends in the market.

Material Composition and Quality

One of the primary determinants of FRP vessel pricing is the composition and quality of the materials used in their fabrication. FRP is created by combining a polymer matrix with reinforcement fibers, which are typically glass, carbon, or aramid. The type of fibers used and the ratio of reinforcement to resin can greatly affect the vessel's strength, durability, and cost. For instance, carbon fiber-reinforced plastic (CFRP) vessels tend to be more expensive due to their superior strength-to-weight ratio and reduced susceptibility to corrosion compared to glass fiber-reinforced plastic (GFRP) vessels.

Size and Complexity

The size of the vessel is another crucial factor influencing its price. Larger vessels require more material, leading to higher costs. Additionally, the complexity of the design plays a significant role in the overall pricing. Custom shapes, intricate designs, and specialized internal configurations can increase manufacturing costs, as they often require more labor and advanced fabrication techniques. Buyers must weigh the benefits of having a custom-designed vessel against the additional expense it incurs.

Manufacturing Process

The manufacturing process used to create FRP vessels can also impact pricing. There are several methods for producing FRP, including hand lay-up, spray-up, filament winding, and compression molding. Each method has its own cost implications, efficiency levels, and quality outputs. Hand lay-up, while cost-effective for small-scale production, is labor-intensive and can result in higher prices for individual units. In contrast, filament winding is suitable for large-scale production, leading to lower costs per unit, but may not be ideal for all shapes and sizes.

frp vessel price

Regulatory Compliance

In industries where safety and compliance are paramount, such as food and pharmaceuticals, FRP vessels must meet stringent regulatory standards. Ensuring compliance with these regulations often requires additional testing, certification, and adherence to specific manufacturing practices, all of which can contribute to higher prices. Buyers must consider whether the compliance costs justify the benefits of using FRP vessels in their applications.

Market Trends and Demand

Market trends also play a significant role in shaping FRP vessel prices. In recent years, there has been a growing demand for eco-friendly and sustainable materials across various sectors. This shift toward greener alternatives has led to an increase in the adoption of FRP vessels. As demand rises, manufacturers may adjust their pricing strategies, potentially leading to increased costs.

Additionally, fluctuations in raw material prices can impact the overall pricing of FRP vessels. Economic trends, supply chain disruptions, and geopolitical factors can all contribute to volatility in the prices of resin and reinforcement materials, subsequently affecting the end cost of the vessels.

Conclusion

In summary, the pricing of FRP vessels is influenced by multiple factors including material quality, size, manufacturing processes, regulatory compliance, and market trends. As industries continue to recognize the benefits of FRP for various applications, understanding these pricing dynamics becomes essential for buyers. By carefully considering these elements, companies can make informed decisions that align their operational needs with budgetary constraints, ultimately maximizing the value of their investments in FRP vessels.

-

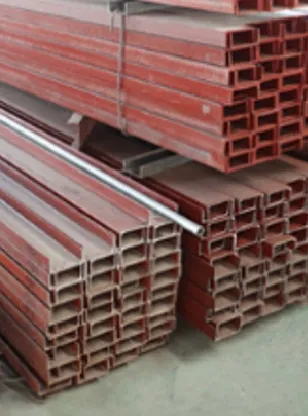

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025