loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP U Channel for Versatile Structural Applications and Lightweight Solutions

Understanding FRP U Channels A Comprehensive Overview

Fiber Reinforced Polymer (FRP) U Channels have become a significant choice in various construction and industrial applications, offering unparalleled advantages over traditional materials like steel and concrete. As the world shifts toward more sustainable and durable building materials, FRP U Channels present a valuable option worth exploring.

What are FRP U Channels?

FRP U Channels are structural components made from a combination of polymer resins and fibers, typically glass, carbon, or aramid. The U-shaped design allows for remarkable versatility, providing support and structural integrity in various applications without the excessive weight typically associated with metals. The unique properties of FRP materials make U Channels suitable for environments that require high resistance to corrosion, chemicals, and harsh weather conditions.

Advantages of FRP U Channels

1. Lightweight One of the standout features of FRP materials is their lightweight nature. This characteristic simplifies handling and installation, reduces transportation costs, and allows for the design of lighter structures without compromising strength.

2. Corrosion Resistance Unlike steel that is prone to rust and degradation when exposed to moisture, FRP U Channels are inherently resistant to corrosion. This makes them ideal for use in marine environments, wastewater treatment plants, and chemical processing facilities, where exposure to corrosive substances is a concern.

3. Durability FRP materials boast exceptional durability and can withstand extreme weather conditions. Their resistance to moisture, UV light, and temperature variations ensures longevity and reduces maintenance costs over time.

frp u channel

4. High Strength-to-Weight Ratio FRP U Channels possess an impressive strength-to-weight ratio, delivering the structural integrity required for support while remaining lightweight. This allows for innovative architectural designs, further expanding the possibilities for builders and designers.

5. Electrical Non-Conductivity For applications in environments where electrical conductivity could pose safety risks, such as electrical substations or certain manufacturing facilities, the non-conductive nature of FRP U Channels is a significant advantage.

6. Customizable The manufacturing process for FRP allows for a high degree of customization. U Channels can be produced in various sizes, shapes, and colors, catering to the specific needs of projects and enhancing aesthetic appeal.

Applications of FRP U Channels

FRP U Channels find applications in multiple industries, including

- Construction Used for structural support in buildings, bridges, and walkways. - Marine Ideal for shipbuilding and coastal infrastructure due to their corrosion resistance. - Transportation Employed in railways and highways for bridge supports and retaining walls. - Chemical Industry Utilized in tanks, pipes, and structures to handle harsh chemicals. - Electrical and Telecommunications Used for mounting various equipment in substations and towers.

Conclusion

As the demand for robust, lightweight, and sustainable building materials continues to grow, FRP U Channels stand out as a compelling choice. Their unique properties address many challenges faced in construction and industrial applications, offering solutions that are not only efficient but also environmentally friendly. By integrating FRP U Channels into projects, industries can enjoy benefits such as reduced weight, enhanced durability, and lower maintenance costs, paving the way for a more innovative and sustainable future. As technology advances and manufacturing processes become more refined, the potential uses for FRP U Channels will continue to expand, cementing their place in modern engineering and architecture.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

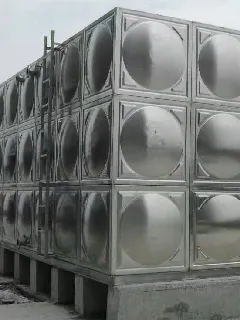

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025