loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

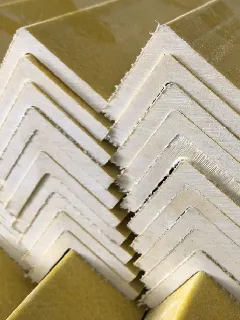

frp u channel

Understanding FRP U Channels Their Properties and Applications

Fiber Reinforced Polymer (FRP) U channels are a versatile and innovative solution in the construction and manufacturing industries. As materials increasingly shift toward lightweight, durable, and corrosion-resistant options, FRP U channels have stood out due to their unique properties and myriad applications. This article explores the characteristics of FRP U channels, their benefits, and various uses across different sectors.

What are FRP U Channels?

FRP U channels are structural components shaped like the letter U, typically made from composite materials that combine fiberglass, resin, and other reinforcement materials. These channels are designed to withstand various loads while maintaining a lightweight structure, making them ideal for numerous applications where traditional materials may fall short.

Properties of FRP U Channels

1. Lightweight One of the most significant advantages of FRP U channels is their lightweight nature. Compared to steel or aluminum, FRP offers a substantial weight reduction without compromising strength. This feature makes handling and installation easier and reduces transportation costs.

2. Corrosion Resistance FRP materials exhibit outstanding resistance to chemical and environmental degradation. Unlike metals that can rust or corrode, FRP U channels can withstand exposure to harsh chemicals, moisture, and extreme weather conditions, which contributes to their longevity and reduces the need for maintenance.

3. High Strength-to-Weight Ratio Despite being lightweight, FRP U channels maintain an impressive strength-to-weight ratio. This means they are capable of supporting significant loads, making them suitable for various structural applications.

4. Thermal and Electrical Insulation FRP is an excellent insulator, both thermally and electrically. This property makes FRP U channels beneficial in applications where thermal management and electrical properties are critical, such as in electrical enclosures and roofs.

5. Adaptability FRP U channels can be easily molded and customized to fit specific requirements, offering flexibility in design for different projects. Manufacturers can tailor the properties of the composite to suit defined performance parameters, whether it be increased fire resistance or enhanced load-bearing capabilities.

frp u channel

Applications of FRP U Channels

The unique attributes of FRP U channels lead to diverse applications across various fields

1. Construction Industry In the construction sector, FRP U channels are employed for structural elements, support systems, and as part of prefabricated structures. Their corrosion resistance makes them ideal for use in environments prone to moisture, such as bridges, pedestrian walkways, and marine applications.

2. Transportation In the transportation industry, these channels are used as part of lightweight flooring systems, railings, and supports for machinery. The reduction in weight contributes to overall fuel efficiency in transport vehicles.

3. Electrical and Telecommunications FRP U channels are commonly utilized in electrical and telecommunications systems as conduits and protective structures. Their insulation properties ensure safety and efficiency while guarding sensitive electrical equipment from environmental damage.

4. Wind Energy The renewable energy sector has also adopted FRP U channels in wind turbine construction, where lightweight and corrosion-resistant materials are crucial for the overall efficiency and durability of the turbines.

5. Water Treatment and Management In water treatment facilities, FRP U channels are utilized in structures that deal with wastewater and corrosive chemicals, providing long-lasting support that can withstand the harsh environment.

Conclusion

FRP U channels represent a significant advancement in material science, offering numerous benefits over traditional materials. Their lightweight nature, exceptional resistance to corrosion, and versatility make them suitable for various industries, from construction to renewable energy. As innovation continues to push the boundaries of what's possible with composite materials like FRP, the applications for U channels will likely expand, providing efficient and sustainable solutions for modern engineering challenges. Embracing such materials not only enhances performance but also contributes to a more sustainable future in infrastructure and design.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025