loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Versatility of FRP Structural Shapes in Modern Engineering Applications

FRP Structural Shapes Revolutionizing Construction and Design

Fiber Reinforced Polymer (FRP) has emerged as a game-changing material in the construction and design industries. As a composite material made of a polymer matrix reinforced with fibers, FRP combines lightweight properties with exceptional strength and durability. This article explores the significance of FRP structural shapes, their applications, advantages, and future trends.

Understanding FRP Structural Shapes

FRP structural shapes refer to the various forms and configurations of FRP materials designed for construction purposes. These shapes can include beams, columns, rods, and panels, among others. The versatility of FRP allows for the creation of custom shapes that meet specific engineering requirements, facilitating innovative designs and applications that traditional materials struggle to achieve.

Applications in Construction

The use of FRP structural shapes spans multiple sectors due to their favorable properties. In the construction industry, they are particularly advantageous in

1. Bridge Construction FRP is increasingly used in bridge components due to its high strength-to-weight ratio and resistance to corrosion. Unlike traditional materials such as steel, FRP does not rust, making it an ideal choice for environments exposed to water, such as bridges over rivers or coastal areas.

2. Building Infrastructure FRP shapes are utilized in various building applications, including beams, columns, and reinforcement. Their lightweight nature reduces the overall load on structures, translating to lower material costs and easier handling during construction.

3. Marine and Offshore Structures The marine environment presents unique challenges, such as saltwater corrosion. FRP's corrosion resistance makes it a preferred material for docks, piers, and other marine structures.

4. Renewable Energy In the field of renewable energy, FRP is commonly employed in wind turbine blades. The material's strength and durability help enhance efficiency and extend the lifespan of these blades.

Advantages of FRP Structural Shapes

The incorporation of FRP structural shapes in construction brings several advantages

frp structural shapes

- Lightweight FRP materials are significantly lighter than traditional options, such as concrete and steel. This property allows for easier transportation and installation, reducing labor costs and time.

- Corrosion Resistance One of the most significant benefits of FRP is its resistance to corrosion, which means structures can endure harsh environmental conditions without extensive maintenance.

- High Strength-to-Weight Ratio FRP demonstrates remarkable strength compared to its weight. This characteristic allows engineers to design lighter structures that do not compromise on stability or safety.

- Design Flexibility The customizable nature of FRP allows architects and engineers to explore innovative designs that would be difficult to achieve with conventional materials. Curved and complex shapes are easily manufactured, enhancing aesthetic appeal.

Challenges and Considerations

While FRP offers numerous benefits, some challenges need to be addressed before widespread adoption. The initial cost of FRP materials can be higher than traditional materials, which may deter some clients. Additionally, the long-term behavior of FRP under various environmental conditions requires further research to ensure reliability over extended periods.

Proper installation techniques and ongoing maintenance strategies must also be established to maximize the benefits of FRP structural shapes. As knowledge and technology surrounding FRP advance, these challenges are increasingly being mitigated.

Future Trends

The future of FRP structural shapes looks promising. With ongoing advancements in manufacturing technologies, such as automated fabrication techniques and improvements in fiber and resin formulations, the performance characteristics of FRP are expected to enhance further. Additionally, growing awareness about sustainability and the need for resilient infrastructure will likely drive demand for FRP materials, as they are often viewed as environmentally friendly alternatives.

Moreover, integration with smart technologies, such as sensors embedded within FRP structures to monitor performance and structural health, could pave the way for more intelligent infrastructure systems.

Conclusion

In conclusion, FRP structural shapes represent a significant advancement in construction and design, offering a blend of strength, lightweight properties, and corrosion resistance. As industries continue to embrace innovative materials, FRP is poised to play a vital role in the future of engineering and architecture, helping to create structures that are not only functional but also sustainable and aesthetically pleasing. The potential applications and benefits are vast, marking a new era in construction methodologies.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

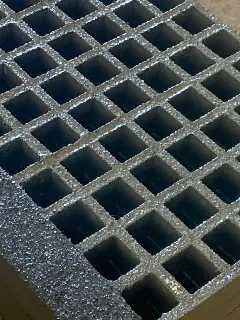

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025