loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp structural sections

FRP Structural Sections An Innovative Approach to Modern Engineering

Fiber Reinforced Polymer (FRP) materials have emerged as a revolutionary solution in the construction industry, particularly in the realm of structural sections. With their combination of high strength, lightweight properties, and resistance to environmental degradation, FRP materials are becoming increasingly popular for various applications, ranging from bridges and building structures to marine environments and industrial settings.

Understanding FRP Materials

FRP consists of a polymer matrix reinforced with fibers such as glass, carbon, or aramid. The integration of these fibers enhances the mechanical properties of the polymers, offering superior strength-to-weight ratios compared to traditional materials like steel and concrete. The most common types of FRP used in structural applications include Glass Fiber Reinforced Polymer (GFRP) and Carbon Fiber Reinforced Polymer (CFRP). Each of these materials brings unique benefits to the table, catering to different engineering needs.

Benefits of FRP Structural Sections

1. Lightweight Characteristics One of the most significant advantages of FRP materials is their lightweight nature. This feature reduces the overall load on structural supports, allowing for more efficient designs and reducing the cost of foundations and supports. This is particularly beneficial in retrofitting existing structures where added weight may compromise stability.

2. Corrosion Resistance Unlike traditional materials that are prone to corrosion from environmental elements, FRP resists chemical and environmental degradation. This characteristic is especially crucial in coastal areas, chemical plants, and other harsh environments where steel might deteriorate quickly. Consequently, FRP materials lead to longer service life and reduced maintenance costs.

3. Design Flexibility FRP can be manufactured into a variety of shapes and sizes, giving engineers unprecedented design flexibility. This adaptability allows for innovative structures that can meet specific aesthetic and functional requirements. Moreover, FRP's ease of fabrication helps streamline the construction process, shortening project timelines.

4. Improved Durability The mechanical properties of FRP materials contribute to their excellent durability. They are not only resistant to moisture and UV radiation but also have superior fatigue resistance. This makes FRP sections a suitable choice for structures that experience cyclic loading conditions, such as bridges and offshore platforms.

frp structural sections

5. Sustainability The production of FRP materials typically involves less energy compared to traditional materials, contributing to a lower carbon footprint. Furthermore, many FRP options are recyclable, aligning with modern sustainability goals within the engineering and construction industries.

Applications of FRP Structural Sections

FRP structural sections have found applications across various sectors

- Bridges Many modern bridges incorporate FRP due to their lightweight properties and resistance to corrosion. For instance, FRP deck panels are used to reduce the overall weight of bridge structures while providing a durable, slip-resistant surface.

- Building Construction FRP is increasingly used for structural reinforcement in multi-story buildings, particularly in seismic zones. It enhances the overall strength of concrete and masonry structures without adding significant weight.

- Marine Applications In shipbuilding and coastal structures, FRP materials are favored for their resistance to saltwater corrosion. They provide strong, lightweight solutions for both structural components and aesthetic elements.

- Aerospace and Transportation The automotive and aerospace industries utilize FRP for weight reduction in vehicle components, leading to improved fuel efficiency without compromising performance.

Conclusion

As engineering challenges evolve and the demand for sustainable solutions increases, FRP structural sections demonstrate significant potential. Their lightweight, durable, and corrosion-resistant properties make them ideal candidates for modern construction practices. As we continue to explore the benefits and applications of FRP materials, it is clear that they will play a crucial role in the future of engineering and construction, paving the way for more resilient and innovative infrastructure. The ongoing research and development in this field promise an exciting future for FRP technologies, cementing their place in our built environment.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

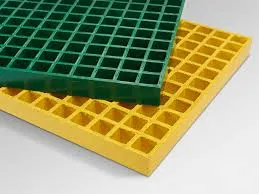

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025