loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

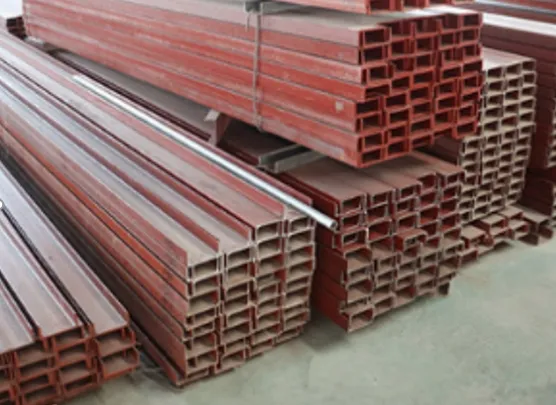

frp structural members

FRP Structural Members Advancements and Applications in Modern Engineering

Fiber Reinforced Polymer (FRP) structural members have revolutionized the construction and engineering industries by providing a combination of lightweight, high strength, and corrosion resistance. Unlike traditional construction materials such as steel and concrete, FRP composites offer unique properties that make them suitable for a wide range of applications, from bridges and buildings to marine structures and infrastructure.

Composition and Properties of FRP

FRP composites are made by combining a polymer matrix, typically epoxy or polyester, with reinforcing fibers like glass, carbon, or aramid. This combination results in materials that possess an impressive strength-to-weight ratio, which allows for lighter structures that do not compromise on strength. Additionally, the resistance to environmental factors such as moisture, chemicals, and UV radiation makes FRP members ideal for use in harsh environments, where traditional materials might corrode or degrade.

One of the key benefits of FRP is its versatility. Different types of fibers can be used to tailor the properties of the composite for specific applications. For example, glass fibers offer good mechanical properties at a lower cost, making them suitable for a wide range of applications, while carbon fibers provide enhanced performance and are often used in specialized or high-performance components.

Design and Engineering Considerations

Designing with FRP structural members involves a different approach compared to conventional materials. The anisotropic properties of FRP, which means that they have different strengths in different directions due to the orientation of the fibers, require engineers to carefully consider load distributions and structural behavior during the design phase. Finite Element Analysis (FEA) and other advanced modeling techniques are frequently used to predict how FRP components will perform under various load conditions.

Moreover, joining FRP members to other materials can present challenges. Traditional welding methods cannot be used, so engineers often rely on adhesive bonding, mechanical fastening, or hybrid systems that integrate FRP with traditional materials. These considerations also influence the design and assembly processes, necessitating specialized training and expertise for construction teams.

frp structural members

Applications Across Industries

The adaptability of FRP structural members has led to a surge in their application across various sectors. In civil engineering, FRP has been effectively used in bridge construction, offering reduced weight and improved resistance to environmental degradation. Prefabricated FRP bridge components can be transported easily and assembled on-site, significantly reducing construction time and labor costs.

In marine applications, FRP members are utilized in shipbuilding and the construction of docks and piers. The inherent resistance of FRP to saltwater corrosion extends the lifespan of marine structures while maintaining their structural integrity. Additionally, FRP composites are increasingly being used in the construction of wind turbine blades and other renewable energy applications, where strength and weight play critical roles in efficiency and performance.

The use of FRP in building retrofitting and strengthening has also gained momentum. Existing structures that may be susceptible to seismic activity or heavy loads can be reinforced with FRP composites, enhancing their load-bearing capacity and extending their useful life without significant structural alterations.

Sustainability and Future Prospects

As concerns regarding environmental sustainability grow, the potential for FRP materials to contribute to greener construction practices is becoming more prominent. Many FRP composites are manufactured using recyclable materials or are themselves recyclable, providing a more sustainable alternative to conventional materials. Furthermore, the lightweight nature of FRP can lead to reduced emissions during transportation and construction.

Looking into the future, ongoing research is focused on enhancing the performance of FRP composites through nanotechnology and bio-based resins, which may lead to even more sustainable and efficient materials. With advances in manufacturing techniques and design methodologies, the integration of FRP structural members into mainstream construction practices is expected to become more prevalent.

In conclusion, FRP structural members offer a forward-looking solution in engineering and construction, merging performance, versatility, and sustainability. As the industry continues to innovate and adapt to new challenges, the role of FRP is likely to expand, heralding a new era of engineering excellence.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025