loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

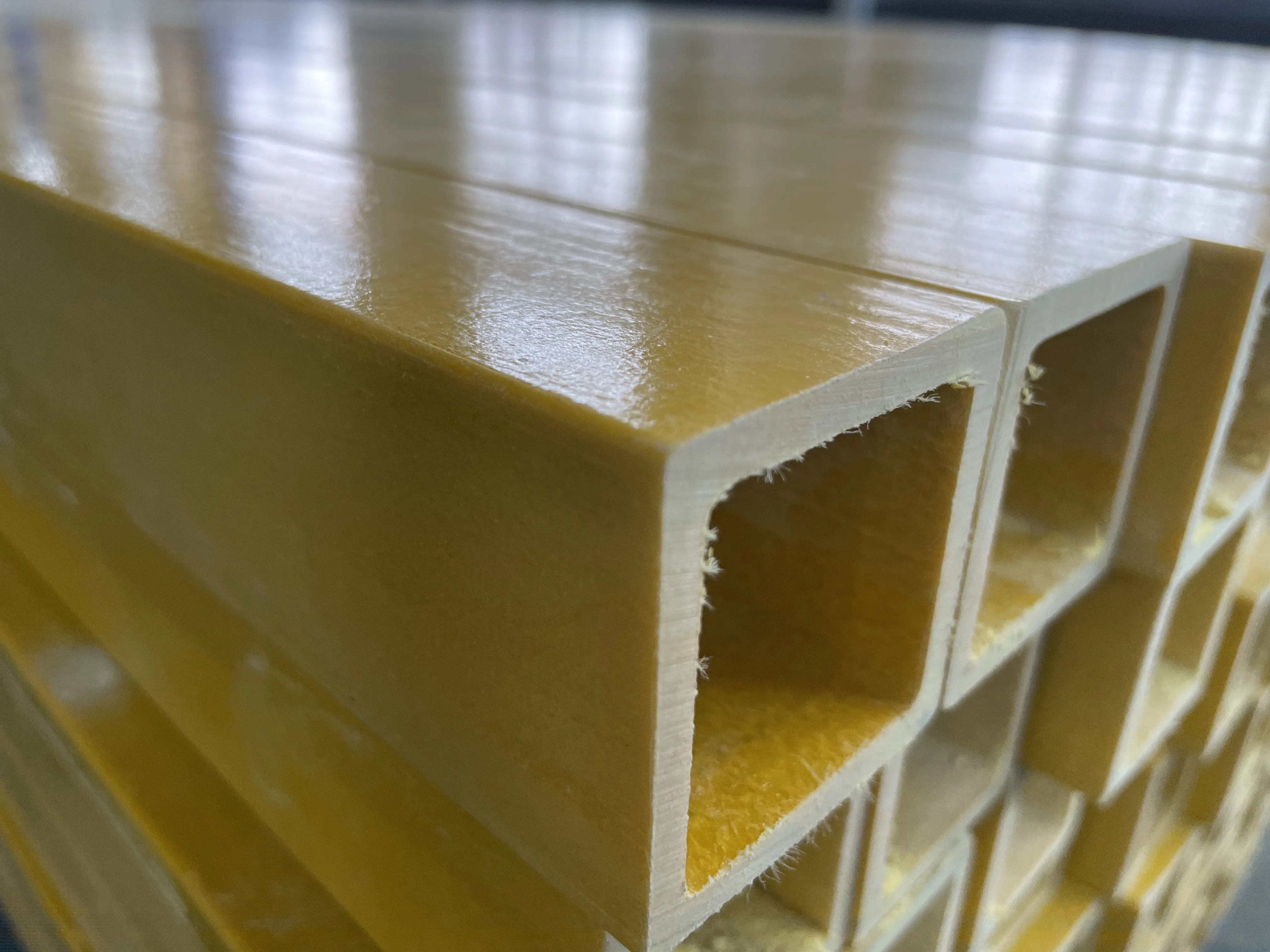

frp square tube

Exploring the Versatility of FRP Square Tubes

Fiber Reinforced Polymer (FRP) square tubes have emerged as a revolutionary material in modern engineering and construction. Combining the lightweight characteristics of polymers with the strength of fibers such as glass, carbon, or aramid, FRP square tubes are transforming traditional building methods and applications in various industries.

Exploring the Versatility of FRP Square Tubes

Moreover, FRP square tubes exhibit outstanding corrosion resistance. Unlike metal, which is prone to rust and degradation when exposed to moisture or chemicals, FRP materials can endure harsh environmental conditions without deteriorating. This attribute makes FRP tubes ideal for applications in chemical plants, wastewater treatment facilities, and coastal structures, where exposure to corrosive elements is a significant concern. Consequently, the lifespan of structures utilizing FRP tubes is extended, leading to lower maintenance costs and enhanced durability.

frp square tube

In addition to their mechanical and chemical properties, FRP square tubes offer design flexibility. They can be manufactured in various dimensions, colors, and configurations to meet specific project requirements. This adaptability allows architects and engineers to create innovative designs that would be challenging to achieve with conventional materials. Whether it’s creating intricate architectural features or supporting structural elements, the versatility of FRP square tubes opens up new possibilities for creative expression in construction.

Furthermore, the thermal insulation properties of FRP materials contribute to energy efficiency in buildings. Unlike metals, FRP square tubes do not conduct heat, helping to regulate indoor temperatures. This characteristic can lead to reduced heating and cooling costs in buildings, underscoring the role of FRP in sustainable construction practices. As the demand for energy-efficient structures grows, the use of FRP materials will likely increase.

The environmental impact of using FRP square tubes is another consideration that is gaining attention. Generally, FRP materials can be manufactured with a lower carbon footprint compared to traditional materials. Additionally, their longevity and resistance to environmental degradation lessen the need for frequent replacements, thus reducing waste.

In summary, FRP square tubes represent a significant advancement in material science, offering a combination of strength, lightweight construction, corrosion resistance, design flexibility, and energy efficiency. Their growing adoption in various sectors, including construction, transportation, and infrastructure, signals a shift towards innovative and sustainable building practices. As technology continues to evolve, the potential applications for FRP materials will undoubtedly expand, further establishing their place within the engineering landscape. The future looks bright for FRP square tubes as they not only improve performance but also contribute to a more sustainable approach to construction and design.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025