loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

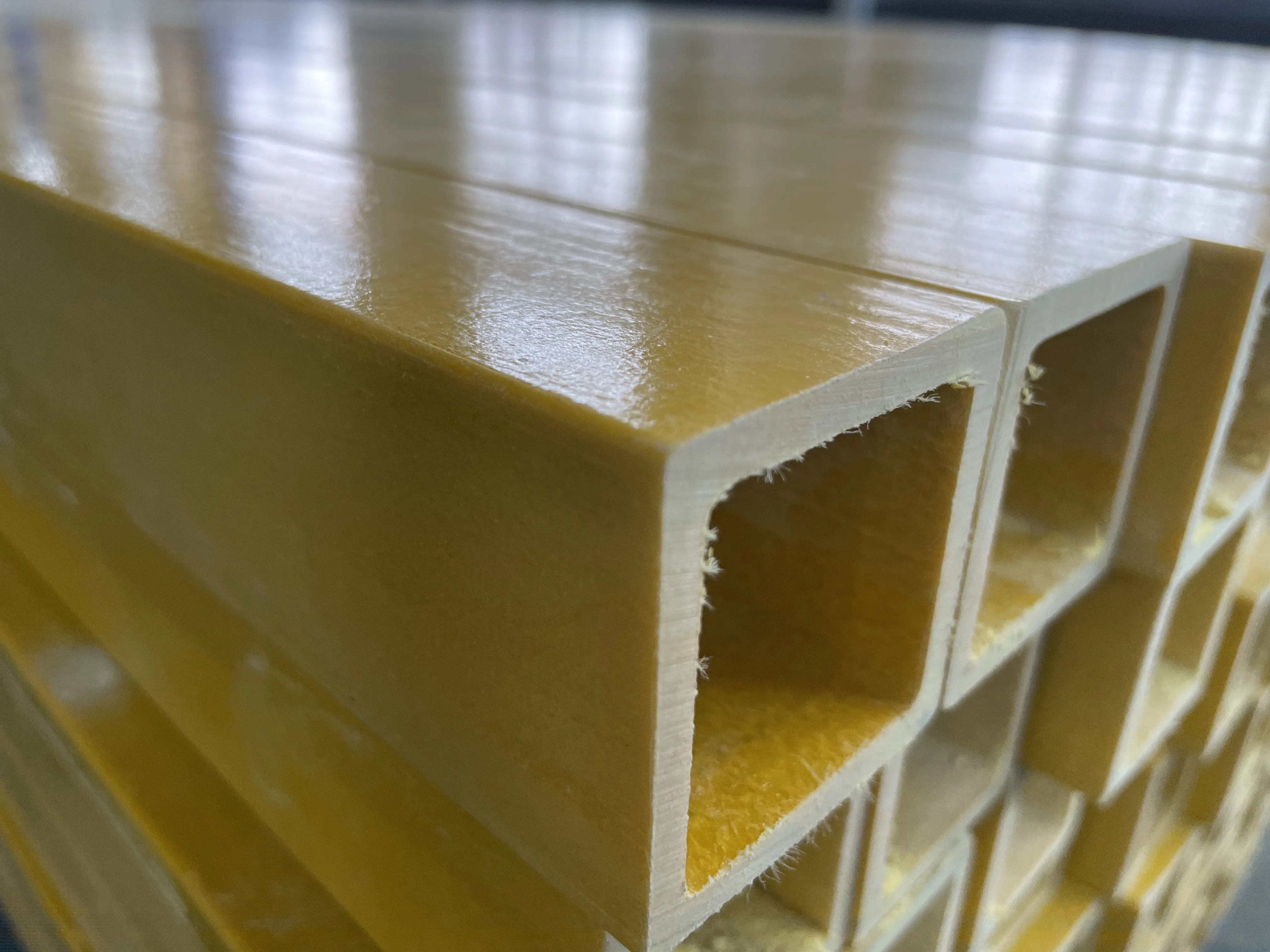

Exploring the Benefits of FRP Square Tubes in Construction Applications

The Versatility and Applications of FRP Square Tubes

Fiber Reinforced Polymer (FRP) square tubes have emerged as a groundbreaking material in various industries due to their unique properties and versatility. Comprising a polymer matrix reinforced with fibers—commonly glass, carbon, or aramid—these square tubes offer a combination of strength, lightweight characteristics, and resistance to environmental factors that make them particularly suitable for diverse applications.

Properties of FRP Square Tubes

One of the standout features of FRP square tubes is their lightweight nature. Compared to traditional materials like steel or aluminum, FRP square tubes weigh significantly less, making them easier to handle and transport. This lightweight characteristic also contributes to reduced structural load, facilitating easier integration into existing frameworks.

Another essential property of FRP square tubes is their high strength-to-weight ratio. They effectively withstand tensile and compressive forces, making them incredibly durable while still being lightweight. This quality makes them suitable for applications in sectors where strength is paramount yet weight savings are critical, such as in the aerospace and automotive industries.

Additionally, FRP square tubes exhibit excellent resistance to corrosion, chemicals, and UV radiation. Unlike metals, they do not rust, ensuring longevity and reduced maintenance costs in harsh environments. As a result, they are increasingly favored in construction, marine, and outdoor applications where exposure to the elements is constant.

Applications of FRP Square Tubes

frp square tube

The versatility of FRP square tubes has led to their adoption in various fields. In the construction industry, they are utilized as structural components in buildings and bridges. Their lightweight nature reduces the overall weight of structures, while their strength ensures stability and safety. Moreover, their resistance to corrosion makes them ideal for use in environments prone to moisture.

In the transportation sector, FRP square tubes are often used in the manufacturing of vehicle components, including frames and supports. The automotive industry benefits from weight reduction, leading to improved fuel efficiency and performance.

Marine applications also see a growing use of FRP square tubes. In boat manufacturing and offshore construction, their corrosion resistance translates into longer-lasting structures that can withstand saline environments. They are used in everything from hulls to support structures for offshore platforms.

The electrical and telecommunications sectors also utilize FRP square tubes for their non-conductive properties. They are often used in the manufacturing of poles and support systems for power lines and communication cables, providing structural support without the risk of electrical interference.

Conclusion

In conclusion, FRP square tubes represent an innovative solution that merges strength, lightweight design, and environmental resilience. Their unique properties make them an ideal choice across various industries, from construction and transportation to marine and electrical applications. As technology advances and the demand for efficient, durable materials increases, the use of FRP square tubes is likely to grow, paving the way for new innovations and applications that leverage their exceptional characteristics. The future is promising for FRP square tubes, as they continue to redefine the possibilities of material science in practical applications.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025