loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

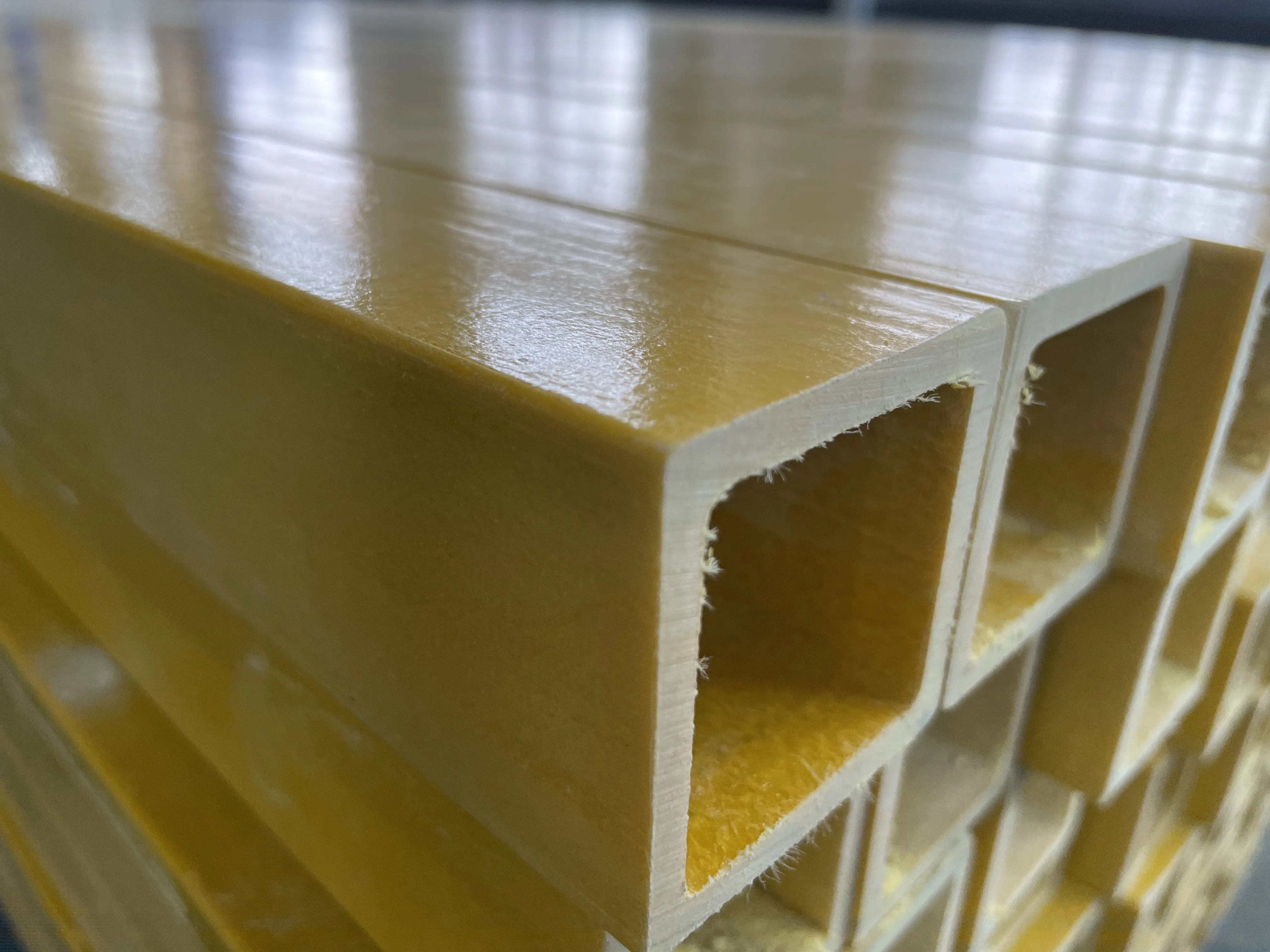

Exploring the Properties and Applications of FRP Square Tubes in Modern Engineering

The Versatility of FRP Square Tubes A Modern Engineering Marvel

In the realm of construction and engineering, materials play a crucial role in determining the integrity and efficiency of structures. One of the most innovative materials that have gained prominence over recent years is Fiber Reinforced Polymer (FRP). Among the various forms in which FRP is available, square tubes are emerging as a preferred choice for a wide array of applications. This article explores the features, benefits, and applications of FRP square tubes, highlighting their rising demand in industry.

Understanding FRP Square Tubes

FRP is composed of a polymer matrix reinforced with fibers, commonly glass, carbon, or aramid. This composite material features excellent strength-to-weight ratios, corrosion resistance, and design flexibility. When prepared in the form of square tubes, FRP gains a distinct advantage in load-bearing applications and structural support. The cube-like profile of FRP square tubes allows for efficient use of the material and optimal structural performance in various engineering scenarios.

Key Advantages of FRP Square Tubes

1. Lightweight and High Strength One of the primary benefits of using FRP square tubes is their lightweight nature, which simplifies handling and installation. Despite being lightweight, they deliver high tensile and compressive strength, making them suitable for both load-bearing and non-load-bearing applications.

2. Corrosion Resistance Unlike traditional materials such as steel or aluminum, FRP is inherently resistant to corrosive environments. This makes FRP square tubes ideal for use in applications exposed to chemicals, moisture, and salt, like coastal structures and industrial plants.

3. Durability and Longevity FRP materials are known for their resilience and durability. They do not suffer from issues like rust, rot, or similar degradation commonly associated with metals and woods. This longevity ensures lower maintenance costs and extended service life of structures using FRP square tubes.

4. Design Flexibility The manufacturing process of FRP allows for tailored designs and sizes to meet specific project requirements. Engineers can customize square tubes in terms of dimensions, wall thickness, and reinforcement configurations, making FRP versatile for various applications.

frp square tube

5. Thermal Insulation Properties FRP materials provide good thermal insulation, making them suitable for applications where temperature regulation is crucial.

Applications of FRP Square Tubes

The unique properties of FRP square tubes make them suitable for a wide range of applications across diverse industries

- Construction and Infrastructure In the construction sector, FRP square tubes are increasingly used in bridge components, scaffolding, and reinforcements for buildings. Their strength and light weight contribute to faster construction and sustainable design practices.

- Marine Applications Given their resistance to corrosion and moisture, FRP square tubes are often utilized in boat building, dock beams, and fishing equipment. They ensure high performance and low maintenance in marine environments.

- Renewable Energy In the wind and solar energy sectors, FRP square tubes serve as support structures for solar panels and wind turbines, thanks to their strength, lightness, and resistance to environmental degradation.

- Aerospace and Transportation The aviation and automotive industries benefit from FRP square tubes in terms of weight reduction and improved fuel efficiency. They are integral to the lightweight structures of modern aircraft and vehicles.

Conclusion

As industries continue to seek sustainable and efficient solutions, FRP square tubes stand out as a modern engineering material with a breadth of applications and advantages. Their unique combination of lightweight, strength, and corrosion resistance makes them an ideal choice in an increasingly demanding market. From construction to renewable energy, the adoption of FRP square tubes reflects a shift toward innovative materials that not only perform exceptionally but also promote sustainability and reduce environmental impact. As technology progresses, the future looks bright for FRP square tubes, paving the way for new advancements and applications in various sectors.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025