loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp softener vessel

Understanding FRP Softener Vessels Importance and Applications

FRP (Fiberglass Reinforced Plastic) softener vessels have gained significant attention in recent years due to their versatility and effectiveness in water treatment processes. These vessels are primarily used for water softening, a crucial step in many industrial and residential applications. As hard water, which contains high levels of calcium and magnesium ions, can lead to various problems, FRP softener vessels provide an efficient solution to mitigate these issues.

One of the primary advantages of FRP softener vessels is their corrosion resistance. Unlike traditional metal tanks that can rust and degrade over time, FRP vessels are designed to withstand harsh environments, including exposure to chemicals and varying temperatures. This durable material ensures longevity and reliability, making it a cost-effective choice for many users.

Understanding FRP Softener Vessels Importance and Applications

Moreover, these vessels can be manufactured in various sizes and configurations, making them suitable for a wide range of applications. Whether in residential water treatment systems or large-scale industrial processes, the adaptability of FRP softener vessels ensures they meet specific needs. Their design can accommodate different flow rates and water capacities, allowing for customization based on the user's requirements.

frp softener vessel

In the context of water treatment, the primary function of a softener vessel is to remove hardness-causing ions from water. This is typically achieved through an ion exchange process, where calcium and magnesium ions are exchanged for sodium ions. The softener contains resin beads specifically designed for this purpose. Over time, these resin beads become saturated with hardness ions, requiring regeneration with a salt solution to restore their functionality.

FRP softener vessels also feature both manual and automatic regeneration systems, providing flexibility in operation. Automatic systems can monitor water quality and initiate regeneration cycles as needed, ensuring efficient operation and minimizing salt consumption. This not only optimizes performance but also contributes to more sustainable water management practices.

In addition to their technical benefits, FRP softener vessels contribute to better water quality, which is crucial in many industries. Softened water reduces scale buildup in pipes, boilers, and appliances, improving their efficiency and lifespan. This is particularly important in industries such as food processing, pharmaceuticals, and manufacturing, where water quality directly impacts product quality and operational efficiency.

The demand for FRP softener vessels is on the rise, driven by increasing awareness of the importance of water treatment and the need for sustainable practices. As more regions face water quality challenges, investing in effective water treatment solutions becomes imperative. FRP softener vessels represent a forward-thinking approach, combining advanced materials with proven technology to enhance water quality.

In conclusion, FRP softener vessels play a vital role in modern water treatment systems. Their corrosion resistance, lightweight construction, and adaptability make them an ideal choice for a variety of applications. By providing effective water softening solutions, they contribute to improved water quality and operational efficiency across multiple industries. As the focus on sustainable water management continues to grow, the relevance of FRP softener vessels will undoubtedly increase, making them a key component in the pursuit of clean and safe water for all.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

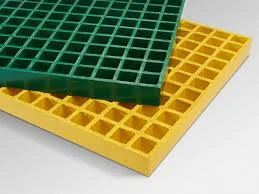

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025