loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp rectangular tube

Understanding FRP Rectangular Tubes Applications and Advantages

Fiber Reinforced Polymer (FRP) rectangular tubes have gained immense popularity in various industries due to their unique combination of strength, light weight, and corrosion resistance. These composite materials are made by integrating fibers, such as glass or carbon, into a polymer matrix. The resulting FRP offers superior performance compared to traditional materials like steel and aluminum.

Understanding FRP Rectangular Tubes Applications and Advantages

Corrosion resistance is another critical benefit of FRP rectangular tubes. Unlike metal structures, which are prone to rust and degradation when exposed to moisture and chemicals, FRP materials maintain their integrity over time. This quality makes them particularly useful in environments subject to harsh chemicals, such as chemical processing plants or wastewater treatment facilities. By using FRP, companies can reduce maintenance costs and extend the lifecycle of their infrastructure.

frp rectangular tube

Moreover, FRP rectangular tubes offer excellent versatility in design. They can be manufactured in various sizes and shapes, tailored to meet specific engineering requirements. This adaptability opens up possibilities for innovative applications in aerospace, automotive, and renewable energy sectors. For example, in wind energy applications, FRP tubes might be used as lightweight supports for turbine blades, improving both efficiency and performance.

The ease of installation is another compelling reason for the increasing adoption of FRP. Compared to traditional materials, FRP is often easier to handle and requires fewer specialized tools for installation. This aspect can result in reduced labor costs and quicker project turnaround times, making FRP an attractive option for contractors and project managers.

In conclusion, FRP rectangular tubes present a combination of strength, light weight, and corrosion resistance that sets them apart from traditional materials. As industries continue to seek ways to improve efficiency and sustainability, the use of FRP is likely to grow. With their wide-ranging applications and numerous advantages, FRP rectangular tubes are poised to play a crucial role in the future of engineering and construction. Whether for building infrastructure, manufacturing components, or enhancing renewable energy applications, FRP tubes are an innovative solution that meets modern demands.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

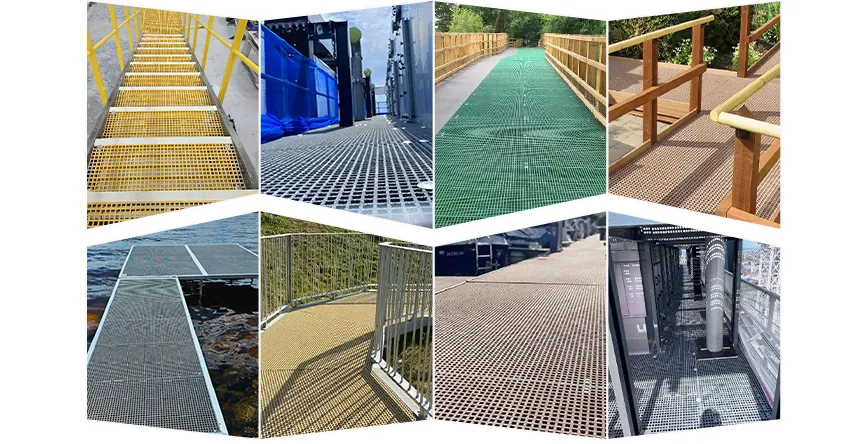

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025