loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp rebar

The Rise of FRP Rebar in Construction

In recent years, the construction industry has witnessed a significant shift towards the adoption of advanced materials, with Fiber Reinforced Polymer (FRP) rebar emerging as a standout option. Traditionally, steel rebar has been the backbone of reinforced concrete structures due to its high tensile strength and ductility. However, the increasing demand for durability, sustainability, and corrosion resistance in construction applications has led engineers and architects to explore the benefits of FRP rebar.

What is FRP Rebar?

FRP rebar is composed of a polymer matrix reinforced with fibers, typically glass, carbon, or aramid. This composite material is designed to provide the structural advantages needed for modern construction while overcoming many of the limitations associated with traditional steel rebar. The production process of FRP involves layering the fibers with an epoxy resin, resulting in a lightweight, strong, and highly durable product.

Advantages of FRP Rebar

1. Corrosion Resistance One of the most significant advantages of FRP rebar is its resistance to corrosion. Unlike steel, which can deteriorate rapidly when exposed to moisture and harsh environmental conditions, FRP does not rust. This characteristic is particularly valuable in structures located in coastal areas or those subjected to de-icing salts, thereby reducing maintenance costs and extending the lifespan of the infrastructure.

2. Lightweight FRP rebar is considerably lighter than steel, making it easier to transport and handle during construction. This lightweight feature can lead to reduced labor costs and simplified installation processes, especially in situations where heavy lifting equipment is not feasible.

3. High Strength-to-Weight Ratio The strength of FRP rebar, particularly when using carbon fibers, can rival that of steel, while still offering the benefit of a lower weight. This balance allows for the efficient design of reinforced structures without compromising on performance.

frp rebar

4. Non-Magnetic and Non-Conductive FRP rebar does not interfere with electromagnetic fields, making it an excellent choice for applications such as hospitals, laboratories, and other facilities where electronic precision is crucial. Additionally, its non-conductive properties enhance safety in environments with high electrical risks.

5. Sustainability As the construction industry moves toward greener practices, the sustainability of materials used becomes critical. FRP rebar can be manufactured using recycled materials, and its longevity contributes to sustainable construction efforts. Furthermore, the reduced need for maintenance and repair translates to lower environmental impact over the lifespan of a project.

Applications in Construction

FRP rebar has found a niche in various construction applications. It is frequently used in bridges, parking garages, tunnels, and marine structures where corrosion resistance is paramount. Its implementation is also gaining traction in residential and commercial buildings, particularly in foundations, slabs, and retaining walls. As technology advances, the versatility of FRP rebar continues to expand, opening doors to innovative construction techniques.

Challenges and Considerations

While FRP rebar presents numerous advantages, it is not without its challenges. The initial cost of FRP is often higher than that of traditional steel rebar, which can deter some builders, despite its long-term benefits. Additionally, the use of FRP rebar requires careful consideration of design parameters, as the behavior of composite materials differs from that of conventional steel. Engineers must be well-versed in the properties and limitations of FRP to ensure optimal performance in structural applications.

Conclusion

As the construction industry continues to evolve, the integration of advanced materials such as FRP rebar represents a promising trend toward more durable, sustainable, and efficient structures. With its remarkable properties, FRP rebar not only meets the demands of modern engineering but also addresses the pressing need for materials that endure the test of time. As awareness and understanding of FRP technology grow, it is likely that we will see an increased adoption of FRP rebar, contributing significantly to the future of construction.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

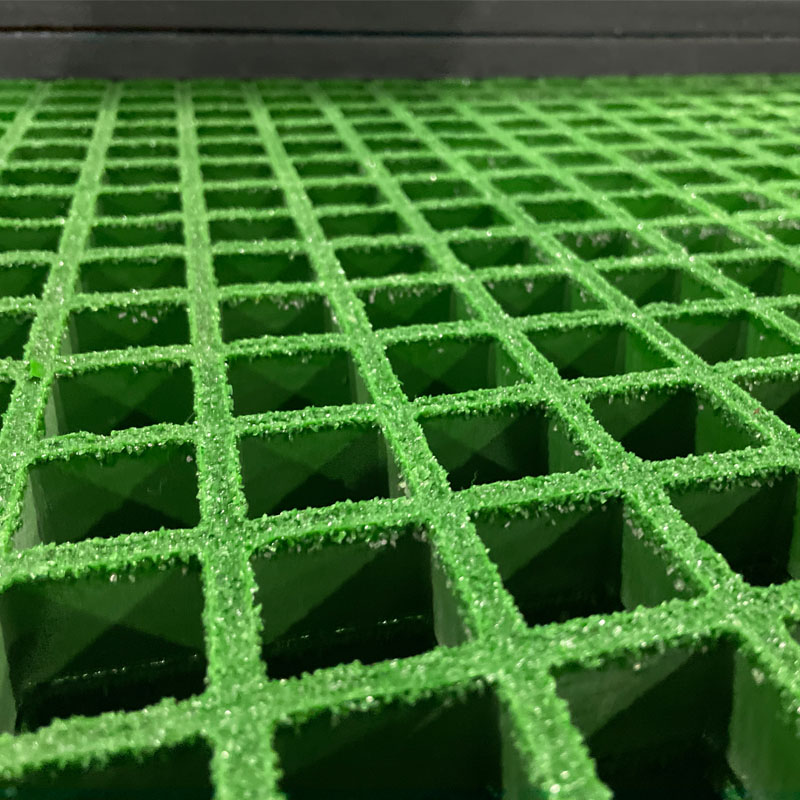

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025