loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Applications of FRP Pultruded Profiles in Construction and Engineering

Understanding FRP Pultruded Profiles Applications, Benefits, and Future Perspectives

Fiber Reinforced Plastic (FRP) pultruded profiles are gaining significant traction across various industries due to their unique blend of properties that cater to modern engineering demands. This article delves into what FRP pultruded profiles are, their advantages, applications, and future perspectives in various sectors.

What are FRP Pultruded Profiles?

FRP pultruded profiles are created through a continuous manufacturing process where fibers (usually glass, carbon, or aramid) are combined with a thermosetting resin. The term “pultrusion” refers to the method of pulling the composite material through a heated die, shaping it into the desired profile while hardening it to form a solid structure. This process allows for consistent, high-performance profiles that can be produced in various shapes and sizes, catering to specific application requirements.

Advantages of FRP Pultruded Profiles

1. Lightweight One of the most significant advantages of FRP profiles is their lightweight nature compared to traditional materials like steel and aluminum. This property makes them easier to handle and install, reducing labor costs and transportation expenses.

2. Corrosion Resistance FRP materials exhibit exceptional resistance to harsh chemicals and environmental factors, making them ideal for use in corrosive environments such as chemical plants, marine applications, and wastewater treatment facilities.

3. Durability The longevity of FRP pultruded profiles is another key benefit. With minimal maintenance required, these materials can withstand years of exposure without degradation, offering a more sustainable option for construction and manufacturing.

4. Mechanical Strength Despite their lightweight nature, FRP profiles have high tensile strength and stiffness, making them suitable for load-bearing applications. Their mechanical properties can be tailored by varying the fiber types and orientations.

5. Thermal Insulation FRP serves as an excellent thermal insulator, reducing energy costs in applications requiring temperature control, such as refrigeration units or construction materials in cold environments.

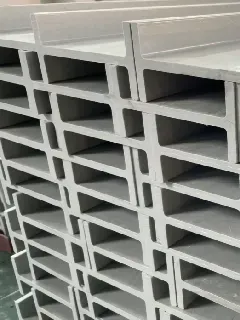

frp pultruded profiles

Applications of FRP Pultruded Profiles

The versatility of FRP pultruded profiles lends them to a wide range of applications

1. Construction In the construction industry, FRP profiles are used for beams, columns, and decking due to their strength-to-weight ratio and resistance to corrosion. They are particularly valuable in bridges, where lightweight elements reduce overall structural load.

2. Transportation The automotive and aerospace industries utilize FRP profiles in manufacturing components that require strength without adding significant weight, contributing to fuel efficiency and performance.

3. Energy Sector In wind energy, FRP is used to create lighter and more efficient turbine blades. Its high strength and low weight enhance energy production capabilities while decreasing maintenance issues.

4. Electrical Utilities FRP profiles are used for poles and structures in electrical utilities due to their non-conductive properties, providing safety and reliability in power distribution.

5. Water Management Their resistance to corrosion makes FRP profiles ideal for pipes, channels, and other infrastructure in water treatment facilities, ensuring longevity in wet environments.

Future Perspectives

The future of FRP pultruded profiles looks promising, bolstered by advances in manufacturing technologies and ongoing research into new composites. As sustainability becomes increasingly crucial in engineering and construction, the potential for recycling and reusing FRP materials is an area of active exploration. Moreover, the growing demand for lightweight yet durable materials in the quest for energy-efficient solutions is likely to drive further innovations in this field.

In conclusion, FRP pultruded profiles represent a significant advancement in material science, offering numerous advantages that address the challenges of traditional materials. Their diverse applications across various industries underscore their importance in modern engineering practices, and as technology continues to evolve, the role of FRP in shaping the future of construction and manufacturing will undoubtedly expand. Embracing the benefits of FRP will ultimately contribute to a more sustainable and efficient world.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025