loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Applications and Benefits of FRP Pultruded Profiles in Modern Construction

Understanding FRP Pultruded Profiles An Innovative Composite Material

In contemporary engineering and construction, the demand for lightweight, high-strength materials has surged. Among the most promising developments in this field is Fiber Reinforced Polymer (FRP) pultruded profiles. These materials combine the best attributes of fibers and polymers, resulting in products that have superior mechanical properties, resistance to environmental degradation, and enhanced aesthetic appeal. This article explores the fundamentals of FRP pultruded profiles, their manufacturing process, advantages, applications, and the future prospects in various industries.

What Are FRP Pultruded Profiles?

FRP pultruded profiles are composite materials formed through a continuous manufacturing process known as pultrusion. This process involves pulling reinforced fibers through a resin bath and then through a heated die where the polymer matrix solidifies. Common fibers used in these profiles include glass, carbon, and aramid, while thermosetting resins, such as epoxy and polyester, are frequently employed as the matrix material.

The result is a lightweight yet robust product that can be manufactured in a variety of shapes, sizes, and colors. The versatility of FRP profiles makes them suitable for a vast range of applications, from construction and infrastructure to automotive and marine industries.

Advantages of FRP Pultruded Profiles

1. Strength-to-Weight Ratio One of the most significant advantages of FRP profiles is their impressive strength-to-weight ratio. They offer mechanical properties comparable to those of steel but are far lighter. This feature allows for easier installation and reduced transportation costs.

2. Corrosion Resistance FRP materials are inherently resistant to corrosion from chemicals and environmental exposure. This quality makes them ideal for use in harsh environments, such as coastal and chemical processing areas where traditional materials would fail.

3. Durability The longevity of FRP pultruded profiles is notable. They do not rust or degrade like metal and have excellent resistance to UV rays, moisture, and other environmental factors. Consequently, structures made from FRP require less maintenance and have a longer lifespan.

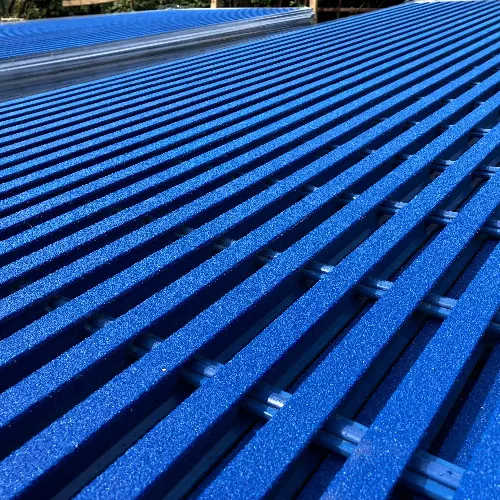

frp pultruded profiles

4. Design Flexibility Pultruded profiles can be manufactured in various shapes and sizes, allowing for innovative design solutions. Architects and engineers can leverage this flexibility to create aesthetically pleasing structures without compromising on performance.

5. Thermal and Electrical Insulation FRP materials possess excellent thermal and electrical insulation properties. This characteristic minimizes heat transfer, making them suitable for applications in electrical enclosures or components requiring thermal insulation.

Applications of FRP Pultruded Profiles

The application spectrum of FRP pultruded profiles is extensive. In construction, they are utilized for creating strong, lightweight beams, columns, and decking systems, providing enhanced structural integrity. In the automotive industry, these profiles contribute to the production of lightweight components that improve fuel efficiency.

Marine applications include boat hulls and deck structures, where corrosion resistance is crucial. Additionally, in the renewable energy sector, FRP profiles are used in wind turbine blades and other structural components, facilitating more efficient and sustainable energy solutions.

Future Prospects

As industries increasingly prioritize sustainability and performance, the demand for FRP pultruded profiles is expected to grow. Advancements in composite manufacturing technologies and the development of bio-based resins are likely to enhance the appeal of FRP materials. Furthermore, as governments and corporations invest in infrastructure and renewable energy projects, FRP will play a critical role in supporting these initiatives.

In conclusion, FRP pultruded profiles represent a significant innovation in materials science. Their unique combination of strength, durability, and versatility positions them as a top choice for a wide array of applications. As technology progresses and new applications emerge, FRP profiles are set to transform the way we approach construction and manufacturing, paving the way for a more sustainable future.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025