loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Jan . 15, 2025 02:20

Back to list

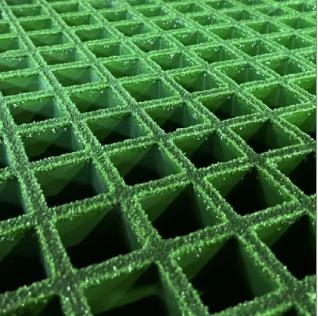

frp pultruded gratings

FRP pultruded gratings have revolutionized industrial flooring, ushering in a new era of durability and safety. Engineered to withstand harrowing conditions, these gratings are setting benchmarks in sectors ranging from construction to chemical processing. Here, we delve into the unparalleled qualities that make FRP pultruded gratings an industry staple, backed by real-world expertise and authoritative insights.

Pultruded gratings are also lauded for their versatile design possibilities. Engineers and architects appreciate the material’s light weight, which simplifies installation without the need for heavy lifting equipment. This ease of customization promotes innovative designs that were previously impractical with heavier, rigid materials. Facilities that utilize FRP solutions benefit from designs tailored to specific operational needs, enhancing both functionality and aesthetics. Regard for environmental impact has also shifted focus towards FRP gratings. Unlike traditional materials, FRP's production leaves a smaller carbon footprint due to its lower energy requirements and less waste generated during manufacturing. As industries continue to evolve towards sustainability, green-certified projects increasingly recognize FRP gratings as they contribute beneficially to eco-friendly objectives. Trust in FRP pultruded gratings is solidified through global certification and compliance with rigorous quality standards. Organizations specializing in material sciences have authenticated the reliability of these gratings through various accreditation programs. ISO standards often endorse FRP products, and this mark of quality assures stakeholders of receiving a premium, reliable product. In conclusion, FRP pultruded gratings are not merely an alternative to traditional grating systems; they represent a tangible leap forward in industrial flooring solutions. Esteemed for their durability, adaptability, and safety features, these gratings engender trust and add value across sectors. They are a testament to the future of smart material applications, unequivocally aligning with industry progression toward innovative, sustainable infrastructure.

Pultruded gratings are also lauded for their versatile design possibilities. Engineers and architects appreciate the material’s light weight, which simplifies installation without the need for heavy lifting equipment. This ease of customization promotes innovative designs that were previously impractical with heavier, rigid materials. Facilities that utilize FRP solutions benefit from designs tailored to specific operational needs, enhancing both functionality and aesthetics. Regard for environmental impact has also shifted focus towards FRP gratings. Unlike traditional materials, FRP's production leaves a smaller carbon footprint due to its lower energy requirements and less waste generated during manufacturing. As industries continue to evolve towards sustainability, green-certified projects increasingly recognize FRP gratings as they contribute beneficially to eco-friendly objectives. Trust in FRP pultruded gratings is solidified through global certification and compliance with rigorous quality standards. Organizations specializing in material sciences have authenticated the reliability of these gratings through various accreditation programs. ISO standards often endorse FRP products, and this mark of quality assures stakeholders of receiving a premium, reliable product. In conclusion, FRP pultruded gratings are not merely an alternative to traditional grating systems; they represent a tangible leap forward in industrial flooring solutions. Esteemed for their durability, adaptability, and safety features, these gratings engender trust and add value across sectors. They are a testament to the future of smart material applications, unequivocally aligning with industry progression toward innovative, sustainable infrastructure.

Share

Next:

Latest news

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025