loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Benefits and Properties of FRP Profiles in Construction and Design

Understanding FRP Profiles Applications and Benefits

Fiber Reinforced Polymer (FRP) profiles have become increasingly significant in the construction and manufacturing industries due to their unique properties and advantages over traditional materials. Composed of a polymer matrix reinforced with fibers, usually glass, carbon, or aramid, FRP profiles are known for their lightweight, high strength, corrosion resistance, and versatility. This article examines the applications, benefits, and future potential of FRP profiles in various sectors.

One of the primary applications of FRP profiles is in the construction sector. With the global drive towards sustainable building practices, FRP materials provide an effective solution for various structural components. They are often used in beams, columns, and slabs, particularly in areas with high exposure to corrosive environments, such as bridges, marine structures, and chemical processing plants. The inherent corrosion resistance of FRP allows for the reduction of maintenance costs and prolongs the lifespan of structures. Furthermore, the lightweight nature of FRP ensures easier handling and installation, potentially lowering labor costs and project timelines.

Understanding FRP Profiles Applications and Benefits

The aerospace industry is another area where FRP profiles shine. Aircraft components, such as wings and fuselage sections, are increasingly incorporating FRP materials to achieve a balance of strength, weight, and durability. The reduced weight of FRP profiles enhances fuel efficiency and payload capacity, making them attractive to aircraft manufacturers striving for more sustainable operations. As technology advances, the use of FRP in aerospace applications is expected to grow, further propelling innovation in the field.

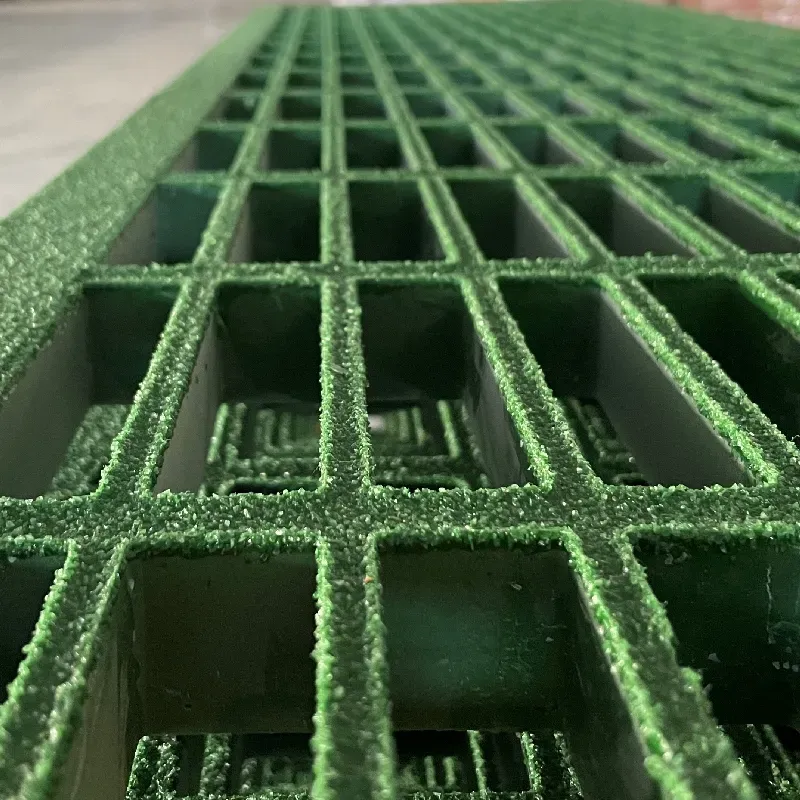

frp profiles

In addition to their applications, FRP profiles offer several benefits over traditional materials. Their resistance to environmental degradation—due to factors such as moisture, chemicals, and UV radiation—ensures that designs remain intact over time with minimal upkeep. This quality is particularly advantageous in marine applications, where saltwater exposure can rapidly deteriorate conventional materials. Additionally, FRP profiles can be tailored to specific requirements, offering a range of shapes, sizes, and mechanical properties to suit diverse needs.

From a sustainability perspective, FRP profiles contribute positively by reducing the carbon footprint associated with construction and manufacturing processes. Their long lifespan and reduced maintenance requirements not only lower resource consumption but also minimize waste. Moreover, advances in recycling technologies are paving the way for the circular economy in the FRP industry, allowing decommissioned materials to be repurposed effectively.

As research and development in FRP technology continue, we can expect further innovations that will enhance their performance capabilities. The integration of smart technologies, such as sensors embedded within the FRP materials, offers the possibility of creating structures that can monitor their own health and performance in real time. Such advancements could lead to safer infrastructures and more efficient maintenance practices.

In conclusion, FRP profiles present a transformative opportunity across various industries, thanks to their unique properties and benefits. Their lightweight, corrosion-resistant, and adaptable nature positions them as a superior alternative to traditional materials, driving advancements in construction, transportation, and aerospace. As we move towards a more sustainable future, the role of FRP profiles is set to become even more critical, fostering innovation and efficiency in an increasingly demanding marketplace.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025