loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Development and Applications of FRP Composite Pressure Vessels in Modern Engineering

FRP Pressure Vessels An Overview of Materials and Applications

Fiberglass Reinforced Plastic (FRP) pressure vessels are becoming increasingly popular in various industries due to their lightweight, corrosion-resistant, and high-strength properties. These structures are essential for storing or transporting liquids and gases under pressure. Unlike traditional materials such as steel or aluminum, FRP combines the beneficial characteristics of its constituent materials, offering superior performance in demanding environments.

Composition and Structure

FRP pressure vessels are primarily composed of a matrix of polymer resin reinforced with glass fibers. The matrix provides the overall shape and protects the fibers, while the glass fibers add strength and rigidity. The typical manufacturing process involves filament winding, where continuous glass fibers are wound around a mandrel in a specific orientation to enhance structural integrity.

One of the significant advantages of FRP is its ability to be tailored for specific applications. By varying the type of resin and the arrangement of glass fibers, engineers can create vessels optimized for particular pressure ratings, chemical resistance, or thermal properties. Common resin types include epoxy, vinyl ester, and polyester, each selected based on the environmental conditions the vessel will face, including temperature and aggressiveness of the chemicals it will contain.

Benefits of FRP Pressure Vessels

1. Corrosion Resistance One of the standout features of FRP pressure vessels is their resistance to corrosion. This property makes them particularly suitable for industries that deal with aggressive chemicals, such as chemical processing, pharmaceuticals, and wastewater treatment. FRP vessels outlast their metal counterparts, reducing maintenance costs and downtime.

2. Lightweight FRP is significantly lighter than traditional materials, which leads to lower transportation costs and easier handling during installation. This feature is particularly advantageous in applications where space and weight constraints are critical, such as in aerospace and marine industries.

frp pressure vessels

3. Thermal Insulation The low thermal conductivity of FRP helps maintain the temperature of the contents without significant heat loss, making them ideal for applications involving heat-sensitive materials.

4. Customization FRP can be molded into complex shapes, enabling the design of uniquely configured vessels for specific functions. This customization extends to sizes, colors, and additional features like flanges or fittings.

Applications

FRP pressure vessels find applications in various fields, including

- Water Treatment Used for storing treated water and chemicals such as chlorine, where corrosion resistance is crucial. - Chemical Storage Ideal for holding corrosive liquids and gases, helping industries maintain safety standards. - Oil and Gas Employed in offshore platforms and refineries for the storage of fuels and other hydrocarbons. - Pharmaceuticals Used in processes requiring strict hygiene and compliance with regulatory standards due to their easy-to-clean surfaces and non-reactivity.

Conclusion

FRP pressure vessels represent a significant advancement in material technology, providing durable and efficient solutions for a range of industrial applications. Their unique properties confer substantial advantages over traditional materials, significantly impacting operational efficiency and safety. As research and technology continue to evolve, FRP vessels are likely to become even more prevalent, paving the way for innovation across multiple sectors. As industries embrace these advanced materials, the future of FRP pressure vessels looks promising, with continuous improvements anticipated in performance, sustainability, and cost-effectiveness.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

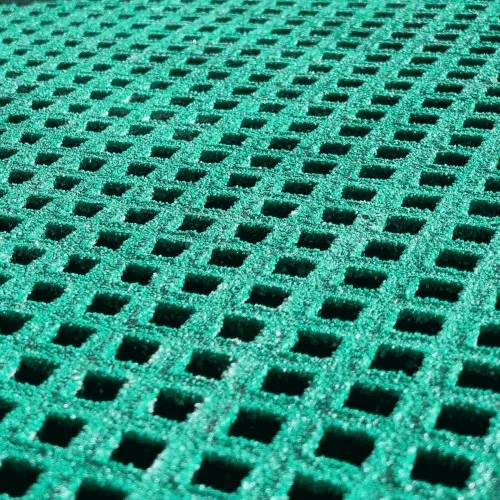

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025