loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Pressure Tank Development and Applications in Modern Engineering Solutions

Understanding FRP Pressure Tanks A Comprehensive Overview

Fiberglass Reinforced Plastic (FRP) pressure tanks have emerged as a popular choice in various industries due to their durability, lightweight characteristics, and resistance to corrosion. These tanks are designed to hold fluids and gases under pressure, making them essential components in applications ranging from water treatment systems to oil and gas operations. In this article, we will delve into the construction, advantages, applications, and maintenance of FRP pressure tanks.

Construction of FRP Pressure Tanks

FRP pressure tanks are constructed using a unique composite material that combines fiberglass with a plastic resin. The process involves reinforcing layers of glass fibers within the resin matrix, providing exceptional strength and rigidity compared to conventional materials like steel or concrete. The manufacturing process typically follows these steps

1. Design and Molding Engineers design the tank according to specific application requirements. A mold is created to shape the tank. 2. Layering Multiple layers of glass fibers are applied within the mold and impregnated with resin. This process can be tailored to achieve the desired thickness and structural integrity.

3. Curing Once layered, the tank undergoes a curing process, during which the resin hardens and bonds the fibers together.

4. Finishing After curing, tanks are demolded and any necessary fittings are installed, such as valves and connections for pressure gauges.

The design of FRP pressure tanks can also incorporate features like insulation and protective coatings to enhance performance and longevity.

Advantages of FRP Pressure Tanks

FRP pressure tanks offer several key advantages over traditional materials

1. Corrosion Resistance One of the most significant benefits of FRP is its inherent resistance to corrosion. Unlike metal tanks, FRP tanks do not rust, making them ideal for industries that handle aggressive chemicals or operate in corrosive environments.

2. Lightweight FRP tanks are significantly lighter than their metal counterparts, making them easier to transport and install. This characteristic also reduces the structural load on supporting frameworks.

3. High Strength-to-Weight Ratio The composite structure of FRP provides strength comparable to steel while being much lighter, making it suitable for applications requiring high durability without the added weight.

4. Customizable FRP can be easily molded into various shapes and sizes, allowing for custom tank designs tailored to specific needs.

frp pressure tank

5. Thermal Insulation The insulating properties of FRP can help maintain the temperature of stored fluids, which is beneficial in various processes.

Applications of FRP Pressure Tanks

The versatility of FRP pressure tanks allows them to be utilized in a broad range of applications, including

- Water Treatment FRP pressure tanks are commonly used in filtration systems, holding media such as activated carbon or sand, and in reverse osmosis systems for water purification. - Chemical Storage Industries dealing with chemicals benefit from FRP tanks' resistance to corrosive substances, storing acids, bases, and solvents safely.

- Oil and Gas These tanks are used in oil and gas operations for storing fluids under pressure, including hydraulic fluids and other petroleum products.

- Agriculture In agricultural applications, FRP tanks can store fertilizers and other agrochemicals, reducing the risk of leaks and environmental contamination.

Maintenance of FRP Pressure Tanks

While FRP pressure tanks require less maintenance than traditional tanks, regular inspections and upkeep are still essential to ensure their longevity and performance

1. Visual Inspections Regularly check for any signs of damage, such as cracks or leaks, which can indicate structural integrity issues.

2. Cleaning Clean the interior periodically to prevent the buildup of contaminants. This is particularly important for tanks used in water treatment.

3. Pressure Testing Conduct pressure tests annually to ensure the tank can withstand operational conditions safely.

4. Protective Coatings Depending on the application, applying protective coatings can help prolong the lifespan of the tank by enhancing resistance to environmental factors.

Conclusion

FRP pressure tanks represent a forward-thinking solution for industries requiring efficient, durable, and corrosion-resistant storage options. Their advantages in strength, weight, and versatility make them a preferred choice for a myriad of applications. Understanding their construction, benefits, and maintenance requirements can help businesses make informed decisions regarding their infrastructure and processes. As industries continue to innovate, FRP pressure tanks will likely play an increasingly vital role in ensuring operational efficiency and safety.

-

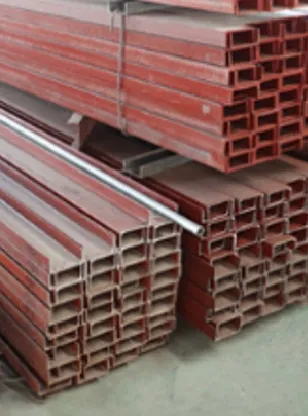

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025