loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

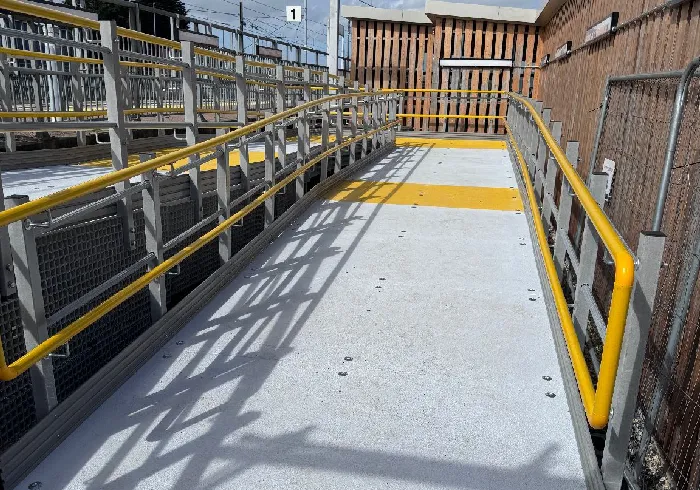

frp post

Understanding FRP (Fiber Reinforced Polymer) A Modern Solution for Various Applications

Fiber Reinforced Polymer (FRP) has emerged as a revolutionary material in contemporary engineering and construction. Combining the properties of polymer matrices with fibers, such as glass, carbon, or aramid, FRPs offer a lightweight, high-strength alternative to traditional materials, making them increasingly popular across various applications. This article delves into the characteristics, advantages, and applications of FRP, giving insight into its growing significance in modern technology and construction.

What is FRP?

Fiber Reinforced Polymer is a composite material that consists of a polymer resin reinforced with fibers. The resin acts as a matrix that binds the fibers together, providing structural integrity, while the fibers enhance the tensile strength and stiffness of the overall composite. The most commonly used fibers in FRP are glass fibers (GFRP), carbon fibers (CFRP), and aramid fibers (AFRP). Each type offers unique properties, making FRP a versatile material suitable for varied applications.

Advantages of FRP

1. High Strength-to-Weight Ratio One of the most significant benefits of FRP is its exceptional strength-to-weight ratio. This means that FRP can deliver high strength without adding significant weight, making it ideal for applications where weight reduction is crucial, such as in aerospace or automotive industries.

2. Corrosion Resistance FRP materials are highly resistant to corrosion, especially when compared to traditional metals. This makes them perfect for use in environments exposed to moisture, chemicals, and other corrosive elements, such as marine and chemical manufacturing applications.

.

4. Design Flexibility FRP can be molded into various shapes and sizes, allowing for innovative designs and applications. This flexibility enables engineers and architects to create structures that are not only functional but also aesthetically pleasing.

frp post

5. Thermal and Electrical Insulation FRP provides excellent thermal and electrical insulation properties. This capability is advantageous in applications where insulation is crucial, such as electrical enclosures and components in electronic devices.

Applications of FRP

FRP's versatility has led to its adoption in various sectors, including construction, transportation, marine, and even sports equipment. Here are some notable applications

- Construction FRP is used in reinforcing concrete structures, such as bridges, parking garages, and buildings. The lightweight nature and resistance to corrosion make FRP an optimal choice for reinforcing beams, columns, and other structural components.

- Transportation In the automotive and aerospace industries, FRP is employed in manufacturing lightweight components, which can lead to improved fuel efficiency and performance. Additionally, FRP is used in the production of bicycles, boats, and protective gear.

- Marine The marine industry utilizes FRP for hulls, decks, and other structural components due to its resistance to saltwater and low maintenance requirements. The lightweight nature of FRP allows for faster vessels and improved performance.

- Sports Equipment FRP is widely used in manufacturing high-performance sporting goods, such as tennis rackets, bicycles, and golf clubs, taking advantage of its lightweight and high-strength properties.

Conclusion

Fiber Reinforced Polymer (FRP) represents a significant advancement in materials science, providing a combination of strength, lightweight properties, and durability. Its resistance to corrosion and flexibility in design make it an ideal choice across various industries, from construction to transportation and beyond. As technology continues to evolve, the applications and benefits of FRP are expected to expand, positioning it as a crucial material for the future. Consequently, understanding and leveraging the advantages of FRP will enable engineers and designers to innovate and create solutions that enhance performance and sustainability in the modern world.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025