loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Advanced FRP Grating Solutions for Enhanced Durability and Performance in Various Applications

Understanding FRP Platform Grating A Comprehensive Overview

In recent years, the use of Fiber Reinforced Polymer (FRP) platform grating has become increasingly popular across various industries. This innovative material offers an array of advantages, making it an ideal choice for applications ranging from industrial flooring to marine environments. This article delves into the key features, benefits, and applications of FRP platform grating, along with its considerations for use in different scenarios.

What is FRP Grating?

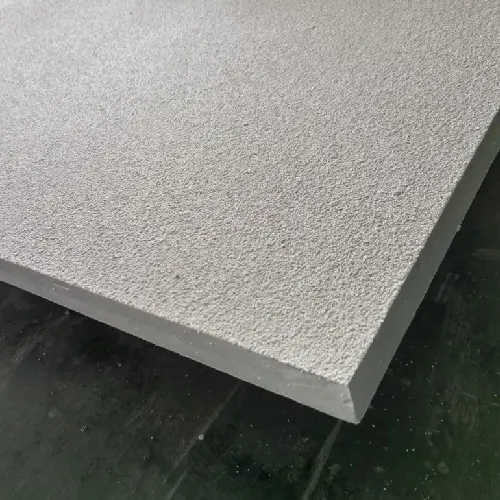

FRP grating is an engineered composite material made from a combination of resin and fiberglass. The intertwining of glass fibers within the resin matrix provides significant strength and stability while remaining lightweight. This unique construction allows FRP grating to outperform traditional materials such as steel and aluminum in various aspects, including corrosion resistance, weight, and ease of installation.

Key Features of FRP Grating

1. Corrosion Resistance One of the most prominent advantages of FRP grating is its excellent resistance to corrosion. Traditional metal gratings can suffer from rust and degradation when exposed to harsh environments, such as chemical plants or marine applications. In contrast, FRP does not oxidize, making it invaluable in chemical processing or coastal locations.

2. Lightweight yet Strong FRP grating is significantly lighter than steel or aluminum alternatives. This characteristic not only simplifies handling and installation but also reduces structural load, making it easier to support and transport.

3. Safety FRP grating typically features a slip-resistant surface, making it safer for foot traffic and machinery, especially in wet or oily conditions. Additionally, its non-conductive properties make it an excellent choice in electrical applications where grounding concerns are paramount.

4. Customizability Manufacturers can customize FRP grating in terms of color, size, and load-bearing capacity. This flexibility means that it can be tailored to meet the specific needs of diverse applications, enhancing its appeal across various sectors.

5. Low Maintenance Unlike metal gratings that may require periodic painting or rust-proofing, FRP grating demands minimal maintenance. This attribute not only contributes to cost savings but also to reduced downtime in operations.

Applications of FRP Grating

frp platform grating

FRP platform grating finds applicability in numerous industries, showcasing its versatility

- Industrial Flooring In factories and warehouses, FRP grating provides a robust and safe flooring solution that can withstand heavy loads and resist chemical spills.

- Marine Applications Boat docks, piers, and other marine structures benefit from FRP's corrosion resistance, enabling longevity even in saltwater environments.

- Wastewater Treatment Plants FRP grating is commonly used in wastewater facilities due to its ability to resist the harsh chemicals and conditions typically found there.

- Pedestrian Walkways Its slip-resistant surface makes FRP an ideal option for pedestrian pathways in parks, outdoor venues, and commercial spaces.

- Oil and Gas Industry In upstream and downstream operations, where exposure to corrosive substances is frequent, FRP grating plays a critical role in safety and durability.

Considerations When Choosing FRP Grating

While FRP platform grating boasts many advantages, it is crucial to consider certain factors before implementation. The type of resin used can affect the grating's performance characteristics, specifically regarding fire resistance, UV stability, and temperature tolerance. Understanding the specific environment and load requirements is essential for selecting the appropriate FRP product.

Moreover, while the initial cost of FRP gratings may be higher than metal options, the long-term savings in maintenance and replacement should be factored into the overall cost analysis.

In conclusion, FRP platform grating represents an advanced, versatile solution for various applications, offering efficiency and durability across multiple industries. As organizations seek to improve safety, reduce maintenance costs, and enhance performance, FRP grating is set to become a staple in infrastructure solutions worldwide. By understanding its features, benefits, and applications, industries can make informed decisions that contribute to sustainable growth and operational excellence.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025