loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Advanced Applications of FRP Molded Grating in Various Industries and Environments

The Advantages of FRP Molded Grating in Various Applications

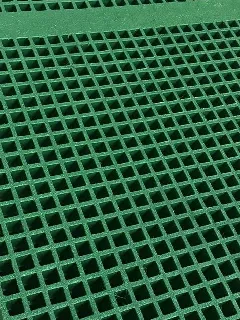

FRP molded grating, or Fiber Reinforced Plastic molded grating, has become increasingly popular across numerous industries due to its unique properties and benefits. This composite material, composed of fiberglass and resin, offers an alternative to traditional materials such as metal and wood. Its applications can be found in construction, infrastructure, chemical processing, and many more areas. Understanding the advantages of FRP molded grating can highlight why it is a preferred choice for many organizations.

One of the primary advantages of FRP molded grating is its exceptional strength-to-weight ratio. This property allows for the creation of sturdy structures without the added burden of excessive weight. Unlike steel grating, which can be heavy and difficult to handle, FRP molded grating is lightweight yet durable, making it easier and safer to install. Workers can maneuver and install the gratings with less risk of injury, which is particularly vital in environments with strict safety regulations.

The Advantages of FRP Molded Grating in Various Applications

In addition to corrosion resistance, FRP molded grating also offers excellent chemical resistance. Many industries deal with harsh chemicals that can quickly deteriorate conventional materials. The chemical stability of FRP means that it can withstand exposure to a wide variety of substances without compromising its integrity. This characteristic makes it a preferable choice for industries such as pharmaceuticals, oil and gas, and food processing, where hygiene and material durability are paramount.

frp molded grating

Notably, FRP molded grating provides a slip-resistant surface, which enhances safety, especially in wet or oily conditions. The molded grating can be designed with a variety of surface textures to improve traction, reducing the risk of slips and falls. This feature is particularly beneficial in industrial and commercial settings where safety is a top priority. With the implementation of FRP grating, companies can create safer work environments and demonstrate a commitment to occupational health and safety.

Moreover, the aesthetic appeal of FRP molded grating should not be overlooked. Available in various colors and finishes, this grating can blend seamlessly into its surroundings or stand out as a design feature. Facility managers and architects often choose FRP molded grating for its versatility in design, allowing them to create visually appealing environments while still meeting functional requirements.

Environmental considerations are also a driving factor in the adoption of FRP molded grating. The production of FRP is more environmentally friendly than that of traditional materials, and its long lifespan contributes to reduced waste. Furthermore, being lightweight, it requires less energy for transportation, further lowering its carbon footprint. As industries become more focused on sustainability, FRP grating emerges as a viable option that aligns with eco-conscious practices.

Finally, the versatility of FRP molded grating permits its use in a variety of applications beyond the industrial sector. It is increasingly being used in commercial settings, such as walkways, platforms, and even decorative elements. Its adaptability allows it to meet the diverse needs of different projects, from functional to aesthetic uses.

In conclusion, FRP molded grating presents a multitude of benefits that make it an advantageous option for many applications. From its impressive strength-to-weight ratio and corrosion resistance to its slip-resistant surface and eco-friendly production, FRP grating proves to be a reliable and smart choice for industries seeking efficient and durable material solutions. As more sectors recognize the advantages of FRP molded grating, it is poised to become a staple in modern construction and industrial applications, reflecting a shift towards advanced materials that enhance safety and sustainability.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025