loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

FRP Louvers Design for Enhanced Cooling Tower Efficiency and Performance

Fiberglass Reinforced Plastic (FRP) Louvers for Cooling Towers

Cooling towers are essential components in many industrial and commercial applications, where they serve to dissipate heat from process systems and help maintain optimal operating temperatures. One crucial element in the design and efficiency of cooling towers is the use of louvers. Among the various materials used, fiberglass reinforced plastic (FRP) has gained significant popularity due to its unique properties and advantages.

Understanding FRP Louvers

FRP is a composite material made of a polymer matrix reinforced with fibers, typically glass. This combination results in a highly durable product that can withstand harsh environmental conditions, making it an ideal choice for cooling towers, which often operate in demanding settings.

Louvers are designed to regulate airflow into the cooling tower while minimizing water and debris ingress. They play a vital role in ensuring the efficiency of the cooling process. When properly designed and installed, FRP louvers can enhance the performance and longevity of cooling towers by providing reliable airflow management.

Advantages of FRP Louvers

1. Corrosion Resistance One of the significant advantages of FRP louvers is their resistance to corrosion. Unlike metal louvers, which can rust and degrade over time when exposed to moisture, chemicals, and temperature fluctuations, FRP does not corrode. This characteristic is particularly beneficial for cooling towers that operate with water and have high humidity levels.

2. Lightweight but Strong FRP louvers are considerably lighter than metal counterparts like aluminum or steel, which simplifies installation and reduces the overall structural load on the cooling tower. Despite their lightweight nature, they maintain high strength, providing excellent structural integrity and wind resistance.

3. Low Maintenance Due to their inherent properties, FRP louvers require minimal maintenance. This characteristic can lead to significant cost savings over time. In environments where access to cooling tower components is challenging, the need for regular inspections and maintenance is minimized, making FRP louvers an attractive option.

4. Thermal Insulation FRP’s insulating properties help to reduce heat transfer, contributing to the overall efficiency of the cooling system. This can lead to energy savings, as cooling towers can operate more effectively with reduced energy consumption.

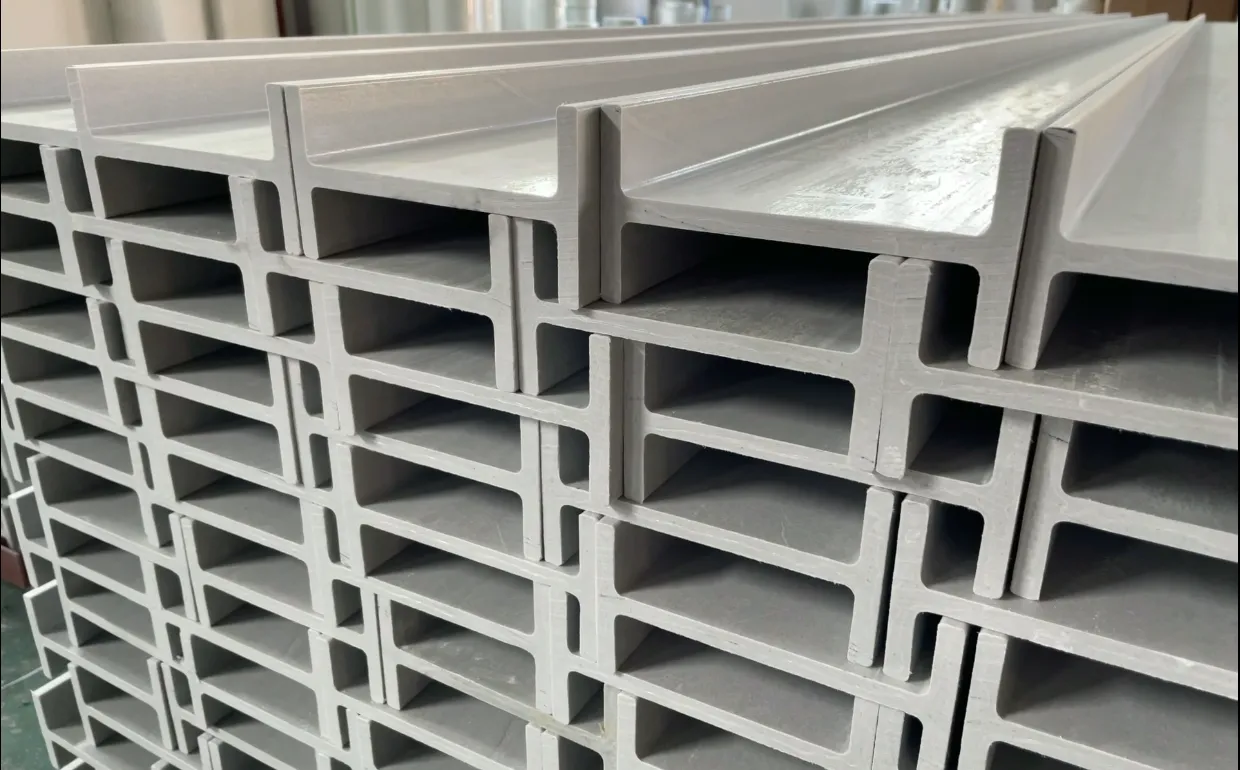

frp louvers for cooling tower

5. Aesthetic Appeal FRP louvers can be manufactured in a variety of colors and finishes, allowing for customization to suit architectural requirements or aesthetic preferences. This versatility can enhance the visual appeal of industrial facilities without compromising on performance.

Applications of FRP Louvers

FRP louvers are widely used in various applications of cooling towers, including

- Power Plants The high demands of power generation facilities require efficient cooling solutions. FRP louvers provide effective airflow management and contribute to the longevity of cooling tower systems.

- HVAC Systems In commercial buildings, HVAC systems rely on cooling towers to remove excess heat. FRP louvers help optimize airflow, ensuring efficient cooling and comfort within the building.

- Chemical Processing The chemical industry often deals with corrosive substances. Utilizing FRP louvers protects against degradation and failure, ensuring reliable operation.

- Food Processing and Pharmaceuticals Environments that demand high hygiene standards benefit from the easy-to-clean surfaces of FRP materials. The non-porous nature of FRP prevents bacterial growth, ensuring compliance with health regulations.

Conclusion

In conclusion, FRP louvers represent a modern solution for cooling tower applications, combining durability, efficiency, and versatility. Their ability to resist corrosion, low maintenance needs, thermal insulation properties, and aesthetic appeal make them a preferred choice for engineers and facility managers. As industries continue to evolve and pursue more sustainable and cost-effective solutions, the role of FRP louvers in cooling towers is likely to expand, contributing to enhanced operational efficiencies and longevity in a variety of industrial applications. By choosing FRP louvers, organizations can invest in a reliable and efficient solution that meets the demands of contemporary cooling systems.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025