loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

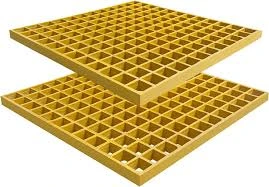

Fiber Reinforced Polymer Grating Panels for Enhanced Structural Applications

Understanding FRP Grating Sheets A Comprehensive Overview

FRP (Fiberglass Reinforced Plastic) grating sheets have garnered substantial attention due to their remarkable properties and multiple applications across various industries. As a composite material, FRP is created by combining fiberglass—a highly durable and lightweight material—with a resin matrix. This results in a product that offers exceptional strength, corrosion resistance, and versatility, making it an ideal choice for many structural and industrial applications.

Key Benefits of FRP Grating Sheets

One of the standout features of FRP grating is its corrosion resistance. Unlike traditional materials like steel or aluminum, which can suffer from rust and degradation when exposed to harsh chemicals and environmental conditions, FRP is largely impervious to such damage. This makes it a preferred choice for installations in chemical plants, wastewater treatment facilities, and marine environments where exposure to corrosive elements is a constant concern.

Furthermore, FRP grating sheets are lightweight, facilitating easier transport and installation. This property reduces labor costs and makes it simpler to work with in challenging environments, especially where heavy lifting is not feasible. Despite their light weight, these grating sheets can handle significant loads, making them suitable for a variety of applications including walkways, platforms, and staircases.

Another noteworthy advantage is the excellent slip resistance that FRP grating offers. Its surface can be designed with a textured finish that provides traction, reducing the risk of slips and falls—an important factor in maintaining safety in industrial settings.

Applications of FRP Grating Sheets

frp grating sheet

FRP grating sheets find usage in diverse sectors. In the industrial realm, they are extensively used in oil and gas facilities, chemical processing plants, and mining operations. The ability of FRP to withstand harsh environments without losing integrity makes it a valuable asset in these applications.

In construction, FRP grating is applied in pedestrian bridges, stairways, and control rooms. Architects often prefer these sheets because they can be molded into various shapes and sizes, offering limitless design possibilities. This flexibility, combined with aesthetic options such as color choices and finishes, enhances the visual appeal of structures.

Furthermore, FRP grating is becoming increasingly popular in the marine sector. Its lightweight nature, combined with resistance to seawater and UV radiation, makes it ideal for docks, marinas, and boat ramps. The use of FRP in these locations promotes longevity while minimizing maintenance costs.

Installation and Maintenance

Installing FRP grating sheets can be straightforward due to their modular design, which allows for easy customization and fitting. Most manufacturers provide detailed installation guidelines, ensuring that even those with limited experience can execute the task effectively. Additionally, the maintenance of FRP grating is minimal; it typically requires just an occasional wash to remove dirt and debris, thanks to its non-corrosive nature.

Conclusion

FRP grating sheets are revolutionizing various industries due to their unique blend of properties that address traditional material limitations. With their corrosion resistance, lightweight design, slip resistance, and versatile applications, FRP grating stands as a testament to innovative material science. As demand continues to grow, it is evident that FRP grating solutions will play an essential role in creating safer, more efficient, and longer-lasting structures across the globe. As industries look toward sustainability and cost-effectiveness, the adoption of FRP grating sheets is likely to increase, paving the way for future advancements in material technology.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025