loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp grating price list

Understanding the Pricing of FRP Gratings A Comprehensive Overview

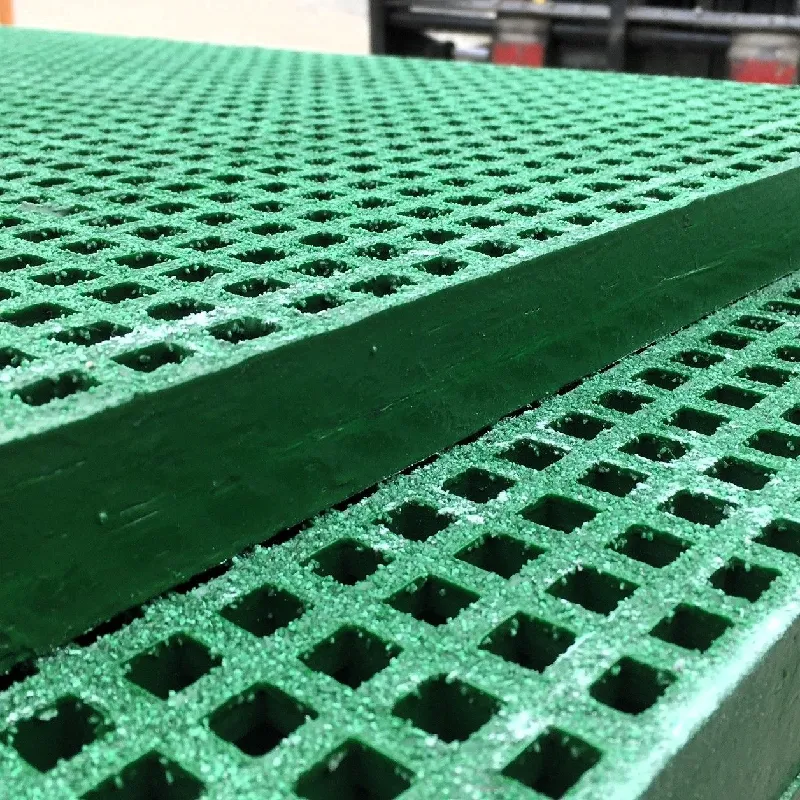

Fiber Reinforced Plastic (FRP) gratings have gained prominence in various industries due to their exceptional durability, lightweight nature, and resistance to corrosion. Typically employed in environments that demand high-performance materials, such as chemical plants, water treatment facilities, and offshore platforms, understanding the pricing of FRP gratings is essential for businesses looking to integrate them into their projects.

Understanding the Pricing of FRP Gratings A Comprehensive Overview

Additionally, the specifications of the gratings, such as their thickness, load-bearing capacity, and dimensions, play a significant role in determining the price. Thicker gratings designed for heavy loads naturally come with a higher price tag due to the additional materials and manufacturing processes involved. Custom-size gratings, while offering flexibility and better fit for specific applications, may also incur extra costs related to production and design.

frp grating price list

Another key element is the manufacturing process. FRP gratings are typically produced using pultrusion or hand lay-up techniques. Pultruded gratings, known for their uniformity and strength, may demand a higher price due to the efficiency of their production method and the consistency in quality. In contrast, hand lay-up gratings, while more affordable, may exhibit variations in strength and surface finish as they involve manual processes.

Market demand and geographic location can also influence pricing. In regions where there is a high demand for FRP products, prices may be elevated due to competition and availability. Conversely, areas with limited access to suppliers may see increased shipping costs, further affecting the final pricing structure.

Furthermore, maintenance and lifecycle costs should be considered when evaluating FRP grating prices. Although the initial investment might be significant, the long-term benefits of FRP gratings—such as reduced maintenance, longevity, and safety—often result in substantial cost savings over time.

In conclusion, while the pricing of FRP gratings can vary significantly based on resin type, specifications, manufacturing processes, and market factors, understanding these aspects can help businesses make informed decisions. By analyzing these components, customers can better navigate the complexities of FRP grating pricing and select solutions that align with both their budget and operational needs. As industries continue to evolve, the demand for high-quality, durable materials like FRP gratings will surely remain a focal point in engineering and construction projects.

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025

-

FRP Water Tank: High-Performance Storage for Corrosive and Clean Water SystemsNewsJun.20,2025

-

FRP Square Tube: The New Industry Standard for Chemical and Structural ApplicationsNewsJun.20,2025

-

FRP Pultruded Profiles: The Ultimate Choice for Lightweight Structural StrengthNewsJun.20,2025

-

FRP Handrails: The Safer, Smarter, and Stronger Choice for Modern InfrastructureNewsJun.20,2025

-

FRP Grating: The Smart Solution for Durable, Lightweight Industrial FlooringNewsJun.20,2025

-

Why Choose a Galvanized Water Tank for Your Storage NeedsNewsMay.21,2025