loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Pricing Analysis for FRP Grating Solutions in Today’s Market

Exploring the Price Dynamics of FRP Grating

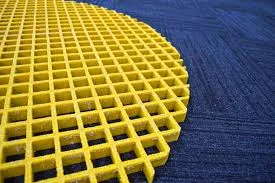

Fiberglass Reinforced Plastic (FRP) grating is a composite material widely used in various industrial applications due to its excellent strength-to-weight ratio, corrosion resistance, and durability. As industries seek materials that can withstand harsh environments while remaining lightweight, FRP grating has gained prominence across sectors such as construction, water treatment, and chemical processing. However, one of the key considerations for manufacturers and end-users alike is the pricing of FRP grating. This article delves into the factors that influence the price of FRP grating and offers insights into market trends.

Understanding FRP Grating

Before diving into pricing, it’s essential to understand what FRP grating is. FRP grating consists of a matrix of fiberglass resin and reinforcing fibers, typically arranged in a grid-like structure. This unique composition provides exceptional mechanical properties, making it a preferred choice for a range of applications, such as walkways, platforms, and safety barriers. Its non-corrosive nature ensures longevity in environments that would otherwise degrade traditional materials like steel or wood.

Factors Influencing FRP Grating Prices

Several key factors contribute to the pricing of FRP grating

1. Material Composition The quality and type of resin used significantly affect the price. For instance, isophthalic or vinylester resins are more expensive compared to polyester resins but offer superior chemical resistance, which may justify the higher cost for specific applications.

2. Manufacturing Process The techniques used in producing FRP grating can influence costs. For example, a grating manufactured through pultrusion might come at a different price point than one made using a mold-casting process. Each method has its cost implications related to energy consumption, labor, and the intricacy of the design.

3. Size and Design Specifications Custom-designed grating tailored to meet specific load-bearing requirements or dimensional constraints will usually be priced higher than standard sizes. Additionally, the thickness and the type of mesh used within the grating can also impact prices.

frp grating price

4. Market Demand and Supply Like any commodity, the price of FRP grating can fluctuate based on market dynamics. A surge in demand from sectors such as construction or renewable energy (like wind and solar) can drive up prices. Conversely, an oversupply could lead to reduced costs.

5. Geographic Location The region where the FRP grating is manufactured or sold plays a crucial role in pricing. Transportation costs, tariffs, and local market conditions can vary significantly, impacting the final price for consumers. For example, regions with limited access to raw materials may face higher costs, while areas with robust manufacturing facilities may benefit from lower prices.

6. Regulatory Factors Compliance with safety and industry standards may introduce additional costs. Products that meet higher regulatory requirements often undergo stringent testing and certification processes, influencing their market price.

Current Market Trends

As of 2023, the pricing landscape for FRP grating appears to be stabilizing after encountering volatility due to global supply chain disruptions. Manufacturers are increasingly focusing on sustainability, leading to innovations in the design and recycling of composite materials, which could eventually lead to a more competitive pricing scenario.

Moreover, the rising awareness of the benefits of FRP grating among various industries is projected to cause an uptick in demand. As more sectors recognize the long-term cost benefits of using FRP grating—such as reduced maintenance costs and enhanced safety—pricing pressures may shift towards a more standardized model, benefiting buyers.

Conclusion

Understanding the pricing of FRP grating is crucial for manufacturers, buyers, and suppliers in making informed decisions. While various factors influence costs, a keen awareness of market dynamics, material choices, and design specifications can help stakeholders navigate the complexities of this essential product. As the world progresses towards more sustainable practices and materials, FRP grating is likely to cement its position as a cost-effective, durable option for a variety of applications, making it a significant player in the materials market for years to come.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025