loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

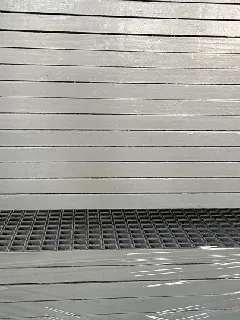

Innovative Fiber Reinforced Polymer Grating Structure for Enhanced Platform Applications

The FRP Grating Platform A Modern Solution for Industrial Applications

In recent years, the industrial landscape has seen significant advancements in materials and construction techniques, one of the most notable being the use of Fiber Reinforced Polymer (FRP) grating platforms. These innovative platforms have emerged as a vital solution for various industrial applications, thanks to their exceptional properties and benefits over traditional materials.

What is FRP Grating?

FRP grating is a composite material made from a polymer matrix reinforced with fibrous materials, usually glass or carbon fibers. This combination results in a lightweight yet strong product that is resistant to corrosion and provides excellent load-bearing capabilities. Unlike traditional steel grating, FRP grating does not rust or corrode, making it highly suitable for environments where exposure to chemicals, moisture, and extreme temperatures is common.

Benefits of FRP Grating Platforms

1. Corrosion Resistance One of the key advantages of FRP grating platforms is their resistance to corrosion. In industries such as wastewater treatment, marine applications, and chemical processing, where harsh environments are prevalent, FRP grating offers a reliable alternative that can withstand the test of time without deteriorating. This resistance results in lower maintenance costs and extended service life.

2. Lightweight and Easy to Install FRP grating is significantly lighter than metal alternatives, making it easier to handle and install. This reduction in weight can lead to lower transportation costs and simplifies the installation process, often requiring fewer workers and specialized tools.

frp grating platform

3. Safety Features FRP grating platforms can be designed with slip-resistant surfaces, enhancing workplace safety in environments where employees may be exposed to wet or oily conditions. This safety feature is crucial in preventing accidents and ensuring a secure working environment.

4. Versatility The adaptability of FRP grating makes it suitable for a wide range of applications, from walkways and platforms to stair treads and trench covers. Its customizable nature allows it to be tailored to meet specific project requirements, catering to diverse industries such as oil and gas, pharmaceuticals, food processing, and more.

5. Electrical Insulation Unlike metal grates, FRP does not conduct electricity. This property is particularly beneficial in environments where electrical hazards may be present, adding an extra layer of safety for workers.

Environmental Considerations

With rising concerns about environmental sustainability, the use of FRP materials presents an eco-friendly option. FRP can often be manufactured from recycled materials, and its longevity reduces the need for frequent replacements, thus minimizing waste. Furthermore, the lightweight nature of FRP contributes to lower energy consumption during transportation and installation.

Conclusion

The adoption of FRP grating platforms marks a significant step forward in material engineering and construction practices. Their corrosion resistance, lightweight properties, safety features, versatility, and environmental benefits make them an ideal choice for a variety of industrial applications. As industries continue to evolve, the integration of FRP technology will undoubtedly play a crucial role in shaping safer, more efficient, and sustainable working environments. The future of industrial platforms is bright with FRP grating leading the way.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025