loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

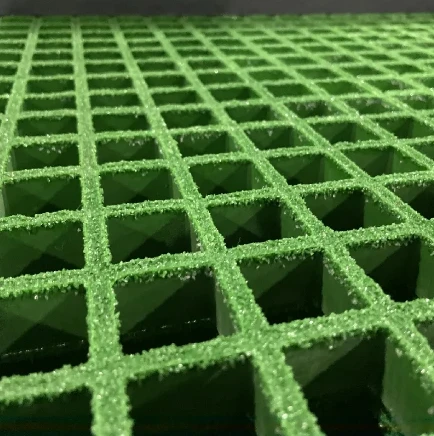

frp grating

Fiber Reinforced Polymer (FRP) Grating A Revolutionary Solution for Modern Infrastructure

In the realm of construction and engineering, the need for durable, lightweight, and corrosion-resistant materials has never been more paramount. Traditional materials like steel and wood, while effective, often succumb to the elements, leading to increased maintenance costs and reduced lifespan. Enter Fiber Reinforced Polymer (FRP) grating—a groundbreaking material that is redefining how we approach infrastructure projects.

FRP grating is composed of a polymer matrix reinforced with fibers, typically glass or carbon. This combination imparts remarkable strength-to-weight ratios and excellent resistance to chemical exposure, making it an ideal solution for various applications, including industrial flooring, walkways, and wastewater treatment facilities. Its lightweight nature also allows for easier installation and reduced transportation costs, which can significantly impact project budgets.

Fiber Reinforced Polymer (FRP) Grating A Revolutionary Solution for Modern Infrastructure

Safety is another critical area where FRP grating excels. Its non-slip surface, enhanced by the incorporation of grit or a textured finish, provides excellent traction even in wet conditions. This characteristic is vital in environments such as manufacturing plants or public walkways where slip hazards could result in severe injuries. Moreover, FRP is inherently resistant to fire, an essential feature for compliance with safety regulations in many jurisdictions.

frp grating

The versatility of FRP grating means it can be easily manufactured to meet specific project requirements. It can be cast in various colors and patterns, allowing for greater design flexibility in architectural and industrial applications. This adaptability not only meets functional needs but can also enhance the aesthetic appeal of a space, making it suitable for public structures and commercial buildings.

Another advantage of FRP grating is its sustainability. As environmental concerns continue to rise, the construction industry is under pressure to adopt greener practices. FRP grating can be made from recyclable materials and contributes to energy efficiency during manufacturing due to its light weight and ease of handling. Its longevity further reduces the frequency of replacements, ultimately leading to lower resource consumption over time.

The installation of FRP grating is straightforward, often requiring fewer tools and less personnel compared to traditional materials. This ease of installation can lead to faster project completion times, which is a significant advantage for contractors and clients alike. In projects with tight deadlines, the efficiency of integrating FRP grating can be a game changer.

Despite its many benefits, there are considerations to keep in mind when choosing FRP grating. It is essential to select the right type of FRP suitable for specific environmental conditions and load-bearing requirements. Consulting with manufacturers or engineers who specialize in FRP can help ensure that the appropriate product is chosen for the intended application.

In conclusion, Fiber Reinforced Polymer grating represents a significant advancement in construction materials. Its unique properties of corrosion resistance, safety, ease of installation, aesthetic flexibility, and sustainability make it an attractive alternative to traditional grating solutions. As the industry moves towards more innovative and environmentally friendly materials, FRP grating stands out as a transformative choice that meets the demands of modern infrastructure while providing long-term economic benefits. Whether used in industrial applications, pedestrian walkways, or architectural designs, FRP grating is poised to play a crucial role in the future of construction, paving the way for safer, more durable, and environmentally conscious structures.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025