loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Innovative Solutions for Durable FRP Floor Grating Systems and Applications

Understanding FRP Floor Grating A Modern Solution for Industrial Flooring

In the continuous evolution of construction and industrial materials, Fiber Reinforced Polymer (FRP) floor grating has emerged as a significant advancement. This article explores the characteristics, benefits, applications, and installation considerations of FRP floor grating, highlighting why it is rapidly becoming a preferred choice in various industries.

What is FRP Floor Grating?

FRP floor grating is a composite material made from a matrix of polymer reinforced with fibers, usually glass or carbon. This combination yields a product that is both lightweight and incredibly strong, making it ideal for applications where traditional materials like steel or wood would be too heavy or susceptible to corrosion.

Key Characteristics

1. Corrosion Resistance One of the most significant advantages of FRP floor grating is its resistance to corrosion. Unlike metal grating, which can rust when exposed to moisture and chemicals, FRP can withstand harsh environments, including chemical factories, wastewater treatment plants, and marine applications.

2. Lightweight The lightweight nature of FRP makes it easier to handle and install compared to heavier materials. This can significantly reduce transportation and installation costs, making it a cost-effective solution for large-scale projects.

3. High Load-Bearing Capacity Despite its lightness, FRP floor grating offers impressive load-bearing capabilities. It can support substantial weight without bending or breaking, making it suitable for heavy-duty applications.

4. Non-Slip Surface Safety is paramount in industrial settings. FRP floor grating can be manufactured with a textured surface to provide enhanced slip resistance, reducing the likelihood of accidents in wet or oily conditions.

5. Customizability FRP grating can be produced in various colors, sizes, and styles. This flexibility allows industries to choose grating that not only meets functional requirements but also aligns with aesthetic preferences.

Applications of FRP Floor Grating

FRP floor grating is used in a variety of industries

frp floor grating

1. Chemical Processing Plants Its resistance to corrosive substances makes it an ideal flooring option for chemical facilities where spills and leaks can occur.

2. Wastewater Treatment In environments where grating is consistently exposed to water and chemicals, FRP provides a reliable and durable solution that doesn’t degrade over time.

3. Marine Applications Seaside facilities benefit from the moisture resistance of FRP, preventing deterioration from saltwater exposure.

4. Food Processing FRP grating is easy to clean and resistant to bacteria growth, making it suitable for food processing areas where hygiene is critical.

5. Power Plants and Utilities The structural integrity and resistance to harsh environments make FRP an ideal choice in power generation facilities.

Installation Considerations

While installing FRP floor grating is generally straightforward due to its lightweight nature, there are still factors to consider

1. Load Requirements Assessing the load requirements for the intended application is crucial. The grating must be designed to handle the specific weights it will encounter.

2. Environmental Factors Understanding the environmental conditions (temperature, moisture, exposure to chemicals) will help in selecting the right type of FRP for the job.

3. Maintenance Although FRP is low-maintenance, regular inspections are essential to ensure its integrity and performance over time.

Conclusion

FRP floor grating represents a significant innovation in flooring solutions within industrial environments. Its combination of strength, corrosion resistance, lightweight nature, and safety features make it an attractive option for many applications. As industries continue to seek materials that enhance efficiency and reduce costs while providing safety and durability, FRP floor grating is poised to play a critical role in the future of industrial construction and design. In an era where sustainability and performance are paramount, FRP solutions are not just a choice; they are becoming the standard.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

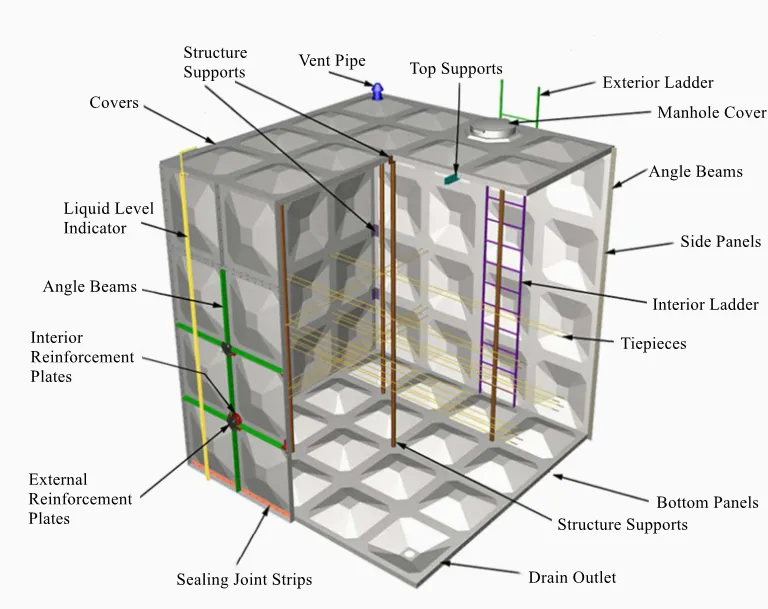

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025