loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp filter vessel

Understanding FRP Filter Vessels Applications and Benefits

Filter vessels are crucial components in various industrial processes, designed to remove impurities and contaminants from fluids. Among the different materials used for constructing these vessels, Fiber-Reinforced Plastic (FRP) has gained prominence due to its unique properties and advantages. This article explores the characteristics, applications, and benefits of FRP filter vessels, highlighting their importance in modern filtration systems.

What are FRP Filter Vessels?

FRP filter vessels are largely composed of a polymer matrix reinforced with fibers, typically glass or carbon fibers. This combination provides the vessel with exceptional strength, durability, and resistance to corrosion. Unlike traditional metal vessels, FRP vessels resist chemical attacks and have a significantly lower weight, making them easier to install and maintain.

The construction process of FRP involves layers of resin and fibers, cured to create a composite material that exhibits superior mechanical properties. This process can be tailored to meet specific requirements such as pressure ratings, sizes, and shapes, thus making FRP filter vessels versatile for various applications.

Key Applications of FRP Filter Vessels

1. Water Treatment One of the primary applications of FRP filter vessels is in water treatment facilities. These vessels are used in both municipal and industrial water treatment processes to remove impurities, suspended solids, and other contaminants. Their corrosion resistance is particularly beneficial in environments where chlorine or other harsh chemicals are present.

2. Chemical Processing In the chemical industry, FRP filter vessels are employed due to their ability to handle aggressive chemicals without degrading. They are used in filtration systems that safeguard sensitive equipment from particulate contamination, prolonging service life and improving operational efficiency.

3. Oil and Gas Industry The oil and gas sector utilizes FRP filter vessels to ensure the purity of fuels and lubricants. These vessels are essential in upstream production and downstream refining processes, helping to prevent clogs and maintain efficiency in processing equipment.

frp filter vessel

4. Food and Beverage FRP vessels are also prominent in the food and beverage industry, where hygiene and safety are paramount. These vessels are used in filtration processes for beverages, ensuring that the final product is free from unwanted particulate matter, while also meeting food safety standards.

Benefits of Using FRP Filter Vessels

1. Corrosion Resistance One of the most significant advantages of FRP filter vessels is their resistance to corrosion and chemical exposure. This property extends their lifespan and reduces maintenance costs, allowing for a more reliable filtration system over time.

2. Weight and Transport FRP filter vessels are considerably lighter than their metal counterparts. This weight reduction not only facilitates easier transport and installation but also minimizes structural load on supporting structures, providing flexibility in design and application.

3. Cost-Effectiveness While the initial cost of FRP filter vessels may be higher than that of traditional materials, their long-term benefits, including reduced maintenance, lower failure rates, and extended operational lifespans, contribute to overall cost savings.

4. Customizability The manufacturing process of FRP allows for tailored solutions, accommodating specific requirements regarding size, shape, and pressure ratings. This customization ensures that the filter vessels meet the unique needs of various applications without compromising performance.

5. Environmental Benefits FRP filter vessels contribute to environmentally friendly practices. Their durability and resistance to degradation reduce the likelihood of leaks and spills, thereby minimizing environmental impact. Additionally, the energy efficiency of water treatment systems is enhanced when using FRP vessels, supporting sustainability efforts.

Conclusion

FRP filter vessels represent a significant advancement in filtration technology, offering a combination of strength, durability, and chemical resistance. Their applications span various industries, from water treatment and chemical processing to food and beverage, emphasizing their versatility. With the increasing demand for efficient and reliable filtration solutions, FRP filter vessels are poised to play a critical role in enhancing operational efficiency and sustainability. As industries continue to evolve, the adoption of innovative materials such as FRP will undoubtedly contribute to the advancement of filtration technologies, benefiting both businesses and the environment.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

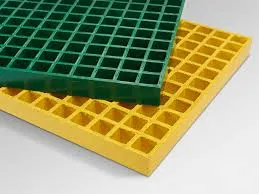

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025