loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

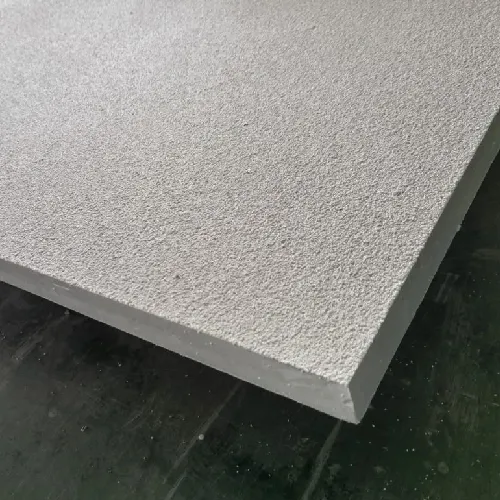

FRP Deck Panels for Enhanced Structural Performance and Durability Solutions

FRP Deck Panels A Revolution in Construction Material

In recent years, the construction industry has witnessed substantial advancements in materials and technologies. One such innovation that has gained momentum is the Fiber-Reinforced Polymer (FRP) deck panel. These panels, which utilize a composite of plastic polymers reinforced with fibers, are quickly becoming a favored choice for various structural applications. This article delves into the advantages of FRP deck panels, their applications, and the future they hold in the construction sector.

Advantages of FRP Deck Panels

FRP deck panels offer a multitude of benefits that make them an attractive option compared to traditional materials like steel or concrete. One of the most significant advantages is their lightweight nature. FRP panels are significantly lighter than steel or concrete, making transportation and installation much more manageable. This can lead to a reduction in labor costs and an overall decrease in construction time.

Another critical benefit is the exceptional strength-to-weight ratio that FRP panels provide. Despite their lightweight composition, these panels can withstand considerable loads, making them suitable for a variety of applications, from pedestrian walkways to heavy-duty industrial platforms. Their corrosion resistance is another noteworthy feature. Unlike steel that may rust over time and concrete that can suffer from chemical degradation, FRP decks remain unaffected by moisture, chemicals, and environmental wear. This durability translates into lower maintenance costs over the structure's lifecycle, providing long-term savings.

Additionally, FRP deck panels are non-conductive and non-magnetic, making them ideal for electrical applications where safety is a priority. Their dimensional stability also ensures that they maintain their shape and structural integrity under varying temperature and humidity conditions, further enhancing their reliability in different environments.

Applications of FRP Deck Panels

frp deck panels

The application of FRP deck panels spans a wide range of industries. In the construction sector, they are utilized in bridges, walkways, and flooring systems, providing safe and durable solutions for both pedestrians and vehicles. Their lightweight nature allows for easier retrofitting in existing structures, which is particularly useful in urban environments where space constraints are a common challenge.

In the industrial realm, FRP panels find their use in manufacturing facilities, chemical plants, and waste treatment facilities. Their resistance to harsh chemicals and environmental factors ensures that facilities can maintain high operational standards without worrying about material degradation. Additionally, FRP deck panels are used in marine applications, such as docks and piers, where traditional materials would be susceptible to corrosion from saltwater exposure.

Future of FRP Deck Panels

As the construction industry continues to evolve, the future of FRP deck panels looks promising. Ongoing research and development aimed at improving the manufacturing processes of these panels are expected to lead to even better performance characteristics and lower production costs. Furthermore, as sustainability becomes a focal point in construction practices, the recyclable nature of FRP materials positions them as an eco-friendly alternative.

The integration of smart technology into FRP panels is another exciting avenue poised for exploration. Sensors could be embedded into the panels to monitor structural integrity over time, offering real-time data that can inform maintenance and safety decisions.

In conclusion, FRP deck panels represent a modern solution to many challenges faced by the construction industry. Their lightweight, strong, and durable characteristics, combined with their versatility in applications, make them an asset for current and future construction projects. As the industry embraces these innovative materials, FRP panels are likely to play an increasingly vital role in building the infrastructures of tomorrow.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025