loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

frp c channel

Understanding FRP C Channels A Versatile Material in Modern Construction

In recent years, the demand for innovative building materials has led to the increasing popularity of Fiber Reinforced Polymer (FRP) C channels. These structural components are the result of combining high-strength fibers with durable polymers, resulting in a material that is lightweight, corrosion-resistant, and remarkably strong. This article delves into the properties, advantages, applications, and future of FRP C channels in construction and engineering.

What are FRP C Channels?

FRP C channels are structural components that resemble traditional steel C channels but are made from composite materials. Typically, they consist of fibers such as glass, carbon, or aramid embedded within a polymer matrix, which provides excellent mechanical properties. The C-shaped design allows for efficient load distribution and makes them suitable for various structural applications.

Key Properties of FRP C Channels

One of the defining properties of FRP C channels is their exceptional strength-to-weight ratio. Compared to steel, FRP components are significantly lighter, which simplifies installation and reduces transportation costs. They also exhibit excellent resistance to corrosion, chemical degradation, and environmental factors, making them ideal for use in harsh conditions, such as coastal areas or industrial environments.

Moreover, FRP C channels have low thermal and electrical conductivity, which can be advantageous in specific applications where electrical insulation is crucial. The flexibility in design also means that they can be tailored to meet specific load and support requirements.

Advantages of FRP C Channels

1. Durability and Longevity The inherent properties of FRP make it resistant to rust, decay, and other forms of wear that often plague traditional materials. This results in longer service life, reducing the need for replacements and maintenance.

2. Lightweight FRP C channels are significantly lighter than their steel counterparts. This not only makes handling and installation easier but also lessens the structural load on supporting components.

frp c channel

3. Design Flexibility The manufacturing process of FRP allows for a wide range of shapes and sizes. Engineers and architects can customize designs without the limitations imposed by steel fabrication methods.

4. Cost-Effectiveness Although the initial cost of FRP materials may be higher than steel, the long-term savings from reduced maintenance, longer lifespan, and quicker installation can make FRP C channels a more economical choice in the long run.

5. Sustainability As sustainability becomes a more pressing concern in construction, FRP materials stand out. They can often be produced with recycled materials and are fully recyclable at the end of their lifecycle.

Applications of FRP C Channels

FRP C channels find applications in a variety of sectors. In the construction industry, they are often used in bridge building, marine structures, and as reinforcements in concrete. Their resistance to corrosion is particularly beneficial in infrastructure exposed to the elements. Additionally, they are increasingly being utilized in the automotive and aerospace industries for components that require a high strength-to-weight ratio.

In the renewable energy sector, FRP C channels are used to support wind turbines and solar panels, as they provide the necessary rigidity and weather resistance. Their versatility is also evident in their applications in the manufacturing of industrial equipment and storage facilities.

The Future of FRP C Channels

As technology advances, the future of FRP C channels looks promising. Ongoing research is focused on improving the composite materials, enhancing their properties, and tailoring them for specific applications. As industries continue to prioritize sustainability and efficiency, FRP C channels are poised to play a critical role in the evolution of modern construction materials.

In conclusion, FRP C channels represent a revolutionary advancement in structural components, offering numerous benefits over traditional materials. Their unique combination of strength, durability, and adaptability makes them an excellent choice for various applications, paving the way for a more sustainable and efficient future in construction and engineering.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

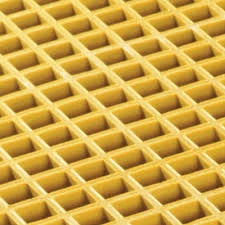

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025