loading...

- No. 9, Xingyuan South Street, Dongwaihuan Road, Zaoqiang County, Hengshui, Hebei, China

- admin@zjcomposites.com

- +86 15097380338

- Welcome to visit our website!

Exploring the Benefits and Applications of FRP C Channels in Construction and Engineering

Understanding FRP C Channels A Modern Approach to Structural Applications

Fiber Reinforced Polymer (FRP) has emerged as a revolutionary material in the construction and engineering industries, offering benefits that traditional materials struggle to match. Among the various forms of FRP, the FRP C channel stands out due to its unique structural properties and wide range of applications. This article explores the characteristics, advantages, and uses of FRP C channels in modern construction.

What is FRP?

FRP is a composite material made from a polymer matrix reinforced with fibers, usually glass, carbon, or aramid. This combination results in a material that is both lightweight and exceptionally strong, exhibiting superior resistance to corrosion, fatigue, and chemicals. The fabrication process of FRP results in profiles like the C channel, which is shaped like the letter C, allowing for versatile uses in structural applications.

Characteristics of FRP C Channels

FRP C channels have distinct properties that make them ideal for various structural applications

1. Lightweight One of the most significant advantages of FRP C channels is their reduced weight compared to traditional steel or aluminum channels. This feature allows for easier handling during installation and reduces transportation costs.

2. High Strength-to-Weight Ratio Despite being lightweight, FRP C channels provide exceptional strength. This makes them suitable for various load-bearing applications while maintaining structural integrity.

3. Corrosion Resistance FRP materials are immune to corrosion, making them an excellent choice for applications in harsh environments, such as chemical plants, marine environments, and wastewater treatment facilities.

4. Durability FRP C channels have a long service life, requiring less maintenance compared to conventional materials. This durability translates into lower lifecycle costs and fewer repairs over time.

5. Design Flexibility The manufacturing process of FRP allows for a high degree of customization in channel sizes, shapes, and colors, catering to specific project requirements.

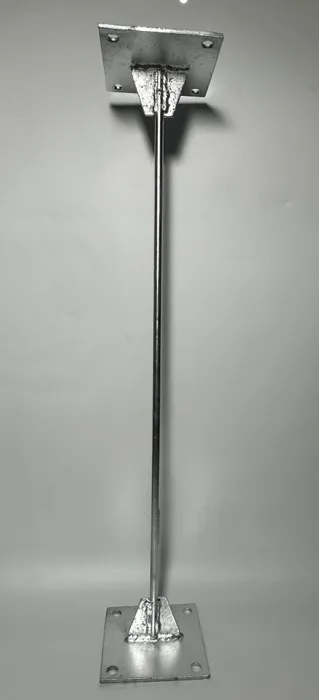

frp c channel

Advantages of Using FRP C Channels

The adoption of FRP C channels in construction brings several notable benefits

1. Cost-Effectiveness While the initial cost of FRP may be higher than traditional materials, the long-term savings due to reduced maintenance and longevity can make FRP C channels a more economical choice over time.

2. Environmental Benefits FRP production processes are more environmentally friendly compared to the mining and processing of traditional metals. Additionally, the longevity and recyclability of FRP contribute to sustainable building practices.

3. Easy Installation The lightweight nature of FRP C channels facilitates quicker and easier installation. This can lead to shorter project timelines and reduced labor costs.

4. Resistance to Thermal Expansion FRP C channels have a lower coefficient of thermal expansion than metals, reducing the risk of warping or structural failure due to temperature changes.

Applications of FRP C Channels

FRP C channels are versatile and can be used in a wide array of applications

- Construction and Infrastructure They are used in building frameworks, bridges, and walkways, where corrosion resistance and strength are paramount. - Industrial Settings In chemical processing plants and waste management facilities, FRP C channels are ideal for supporting equipment and structures that endure harsh conditions. - Transportation They find applications in the transportation sector, including rail and highway infrastructures, due to their durability and lightweight characteristics. - Marine Applications In waterfront facilities and boats, FRP C channels are favored for their resistance to saltwater corrosion.

Conclusion

The FRP C channel represents a significant advancement in structural materials, combining strength, durability, and versatility. With their lightweight nature and resistance to harsh environments, these channels are well-suited for a diverse range of applications. As industries continue to seek more efficient and sustainable construction solutions, FRP C channels are poised to become an even more integral component of modern engineering and architecture, paving the way for innovative building practices.

-

The Rise of FRP Profiles: Strong, Lightweight, and Built to LastNewsJul.14,2025

-

SMC Panel Tanks: A Modern Water Storage Solution for All EnvironmentsNewsJul.14,2025

-

GRP Grating: A Modern Solution for Safe and Durable Access SystemsNewsJul.14,2025

-

Galvanized Steel Water Tanks: Durable, Reliable, and Ready for UseNewsJul.14,2025

-

FRP Mini Mesh Grating: The Safer, Smarter Flooring SolutionNewsJul.14,2025

-

Exploring FRP Vessels: Durable Solutions for Modern Fluid HandlingNewsJul.14,2025

-

GRP Structures: The Future of Lightweight, High-Performance EngineeringNewsJun.20,2025